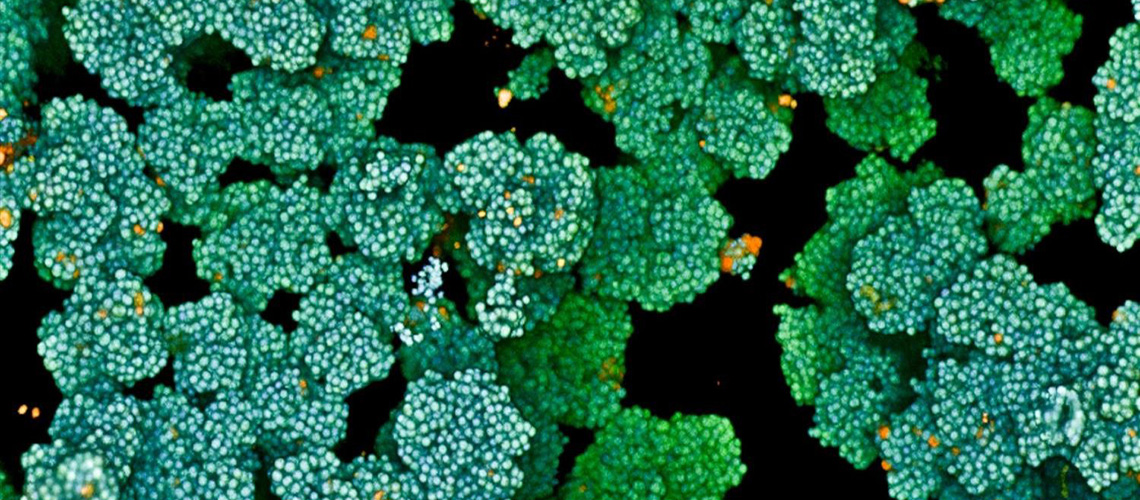

A groundbreaking study by the UNSW Sustainable Materials Research and Technology (SMaRT) Centre has revealed that textile waste can be transformed into activated carbon, offering a sustainable alternative to traditional purification materials. The research, published by Elsevier, explores how end-of-life textiles can undergo a thermal manufacturing process to become activated carbon, a critical component in water, air, and industrial purification systems.

The SMaRT Centre’s findings suggest a significant reduction in the environmental impact associated with the conventional coal-based production of activated carbon. According to Professor Veena Sahajwalla, Director of the SMaRT Centre, this innovative approach could address global waste challenges while providing valuable resources for purification systems.

Transforming Waste into Resources

Professor Sahajwalla emphasized the dual benefits of the research, stating, “We show it is very possible to not only help ameliorate the growing waste textiles problem being experienced globally, but to reform this waste stream usually destined for landfill into highly valued activated carbon materials that can be used in many purification systems.”

The study’s manufacturing process demonstrated a remarkable 36 percent reduction in embodied carbon and over a 99 percent reduction in embodied energy demand compared to conventional coal-derived activated carbon. This marks a significant advancement in sustainable manufacturing practices.

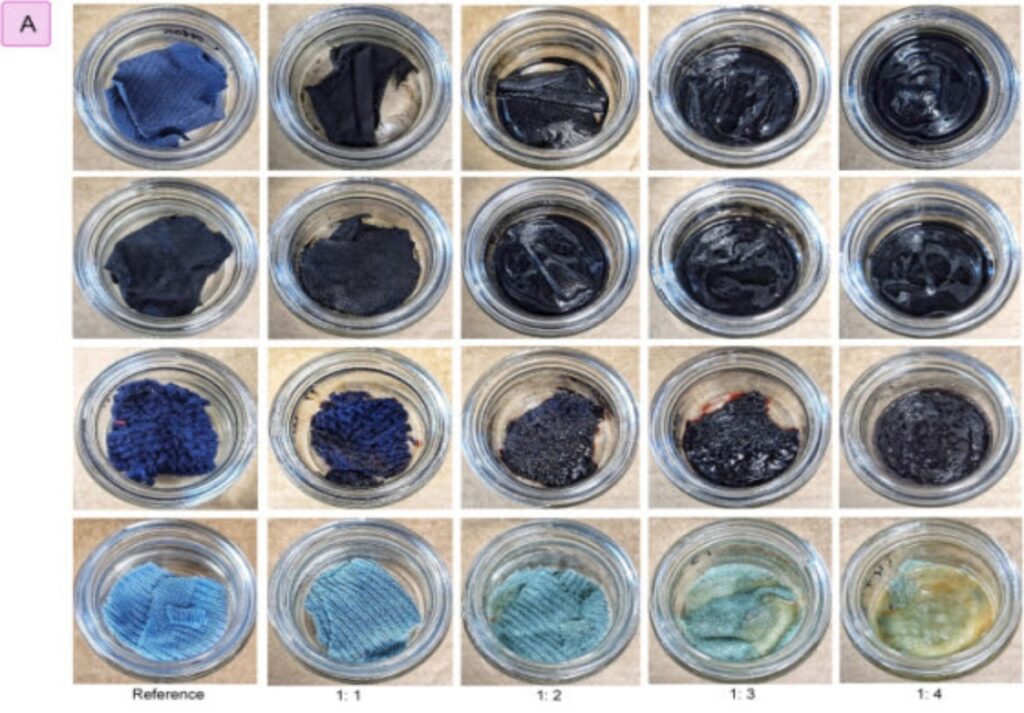

Assessing Textile Suitability

The research assessed 14 common textile types, including cotton, polyester, wool, and blended fabrics. The findings revealed that 11 of these materials are suitable for activated carbon production. However, materials such as polyurethane and leather did not perform well in the process.

A comprehensive lifecycle assessment further indicated improved environmental performance across several impact categories, such as global warming potential and fossil fuel depletion, underscoring the sustainability of this innovative approach.

Implications for Global Purification Systems

This development follows growing concerns about the environmental impacts of traditional purification materials. The UNSW SMaRT Centre’s research supports the development of small-scale manufacturing technologies capable of recovering valuable materials from complex waste streams.

The study was conducted under the Australian Research Council Industrial Transformation Research Hub into Microrecycling, which aims to develop sustainable solutions for hard-to-recycle waste. This initiative is part of a broader effort to create environmentally friendly manufacturing processes that can be adopted globally.

According to the study, the manufacturing process demonstrated a 36 percent reduction in embodied carbon and more than a 99 percent reduction in embodied energy demand compared with conventional coal-derived activated carbon.

Looking Ahead: A Sustainable Future

The move represents a significant step forward in sustainable manufacturing, with potential implications for industries reliant on purification systems. The ability to transform textile waste into valuable resources not only addresses waste management issues but also contributes to reducing the carbon footprint of purification processes worldwide.

As the world continues to grapple with environmental challenges, the UNSW SMaRT Centre’s research offers a promising pathway towards more sustainable industrial practices. The potential for widespread adoption of this technology could lead to significant reductions in waste and energy consumption, paving the way for a cleaner, more sustainable future.

Meanwhile, experts in the field are optimistic about the broader applications of this research. With continued advancements in recycling technologies, the potential to revolutionize waste management and resource recovery is within reach.

The next steps involve scaling up the technology for broader industrial use, with the hope of integrating these sustainable practices into global purification systems. As industries look to reduce their environmental impact, the findings from the UNSW SMaRT Centre could serve as a blueprint for future innovations.