For decades, scientists have been puzzled by the origins of “soft spots” in amorphous materials such as glass. A groundbreaking study now reveals that these regions of mechanical softness are dictated by hierarchical atomic structures, as uncovered through the lens of mathematical topology.

The research, conducted by a team from The University of Osaka, the National Institute of Advanced Industrial Science and Technology (AIST), Okayama University, and the University of Tokyo, sheds light on why certain areas of glass and other amorphous materials deform more readily. By employing persistent homology, a mathematical method, the researchers demonstrated that these soft regions are governed by hidden hierarchical structures where ordered and disordered atomic arrangements coexist.

Understanding Amorphous Materials

Unlike crystalline solids such as salt or ice, which have atoms arranged in neat, repeating patterns, amorphous materials like glass, rubber, and some plastics lack long-range order. However, they are not entirely random; they exhibit medium-range order (MRO), which consists of subtle atomic patterns extending over a few nanometers.

Scientists have long suspected that MRO plays a crucial role in the physical properties of amorphous materials, particularly their mechanical responses. Yet, due to the complexity of these atomic networks, traditional analysis methods have struggled to clarify how MRO relates to regions that deform more easily than their surroundings. Consequently, the structural origins of mechanical softness in amorphous solids have remained elusive.

The Role of Persistent Homology

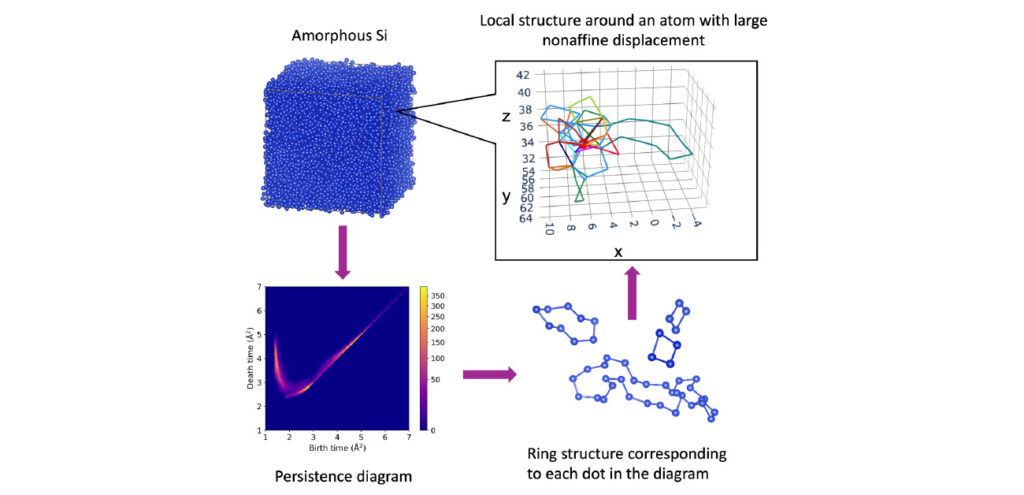

The research team applied persistent homology, a branch of topological data analysis, to capture structural features across multiple scales. In amorphous silicon—a prototypical covalent amorphous material widely used in solar cells and electronic devices—they discovered hierarchical ring structures: smaller rings with irregular edge lengths nested inside larger rings.

This coexistence of order and disorder reveals that softness arises not from randomness alone but from constraints imposed by medium-range order interwoven with local disorder. The study also found that these hierarchical structures strongly correlate with low-energy localized vibrations, a universal feature of glasses known as the “boson peak.”

Expert Insights and Implications

“This work provides a new route to link the atomic structure of amorphous materials with their mechanical responses,” stated Emi Minamitani of The University of Osaka, the lead author of the study. “We believe these insights will accelerate the design of durable glass and other advanced amorphous materials.”

The discovery establishes a clear structural principle: mechanically soft regions arise where disorder is embedded within medium-range order. This counterintuitive finding offers practical guidelines for developing amorphous solids that are both flexible and strong, benefiting applications from displays and coatings to energy devices.

Future Directions and Applications

The implications of this study extend beyond academic curiosity. By understanding the structural principles that govern softness in amorphous materials, researchers can better design materials with tailored mechanical properties. This could lead to innovations in industries ranging from consumer electronics to renewable energy.

As the scientific community continues to explore the potential of topological data analysis in material science, the insights gained from this study may pave the way for new materials that combine flexibility with strength, transforming how we use and interact with everyday materials.

“The article ‘Persistent homology elucidates hierarchical structures responsible for mechanical properties in covalent amorphous solids’ was published in Nature Communications at DOI: https://doi.org/10.1038/s41467-025-63424-z.”

This research not only advances our understanding of amorphous materials but also opens new avenues for material innovation, promising a future where materials are designed with unprecedented precision and functionality.