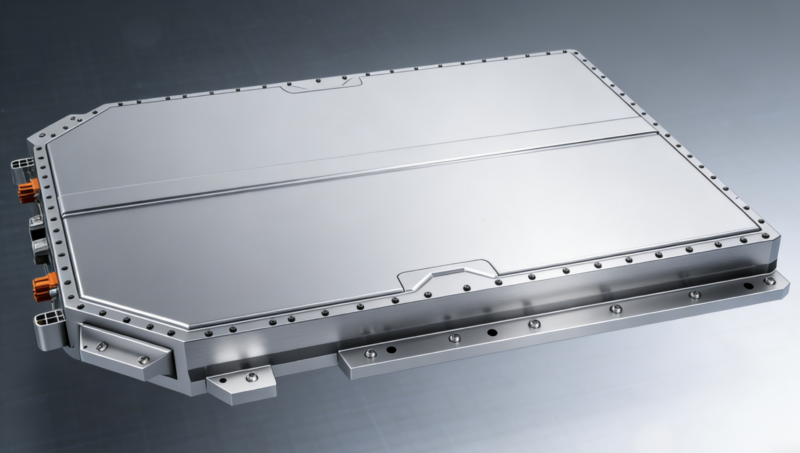

Recent findings by U.S. researchers have shed light on the accelerated aging of certain advanced electric vehicle (EV) batteries, providing critical context for ongoing research in China aimed at restoring performance in degraded lithium-ion cells. According to IT-home, the U.S. study pinpointed internal mechanical stress from uneven electrochemical reactions within single-crystal high-nickel cathodes as a key factor in cracking and capacity loss. This challenges previous assumptions that single-crystal designs inherently offer longer service life.

Research by Argonne National Laboratory and the University of Chicago revealed that conclusions drawn from polycrystalline cathodes were mistakenly applied to single-crystal materials. While single-crystal cathodes eliminate grain boundaries that can cause cracking, the study demonstrated that reaction inhomogeneity within individual particles induces stress, leading to structural failure during repeated charge-discharge cycles.

China’s Innovative Approach to Battery Regeneration

In response to these findings, Chinese researchers have developed laboratory-scale methods to recover usable capacity from aged EV batteries. By the second half of 2025, researchers at Huazhong University of Science and Technology reported success with a molten-salt regeneration technique for aged high-nickel lithium-ion battery cathodes, commonly used in electric vehicles. Public reports indicate that this process restored up to 76 percent of the original discharge capacity in degraded materials, allowing lithium ions to re-enter damaged crystal structures and ameliorate structural disorder formed during long-term cycling.

The study highlighted that many retired EV battery cathodes retain enough structural integrity to enable regeneration at the material level. This makes high-nickel cathodes particularly suitable for restoration research, especially as China’s EV battery retirement market expands rapidly. According to Science and Technology Daily, China is entering a large-scale retirement phase, with a projected surge in end-of-life battery packs, creating favorable conditions for the expansion of regeneration and recycling activities.

Exploring Diverse Chemistries and Regeneration Strategies

A 2025 academic study in China has also explored redox-based regeneration strategies for spent lithium-iron phosphate (LFP) batteries. A comprehensive review by Jiangsu Normal University and collaborators systematically compiles regeneration methods based on oxidation and reduction reactions, outlines pathways to optimize recycled cathode materials, and emphasizes the need for further research across diverse chemistries, as published by RSC.

Industry data indicates that China’s lithium-ion battery recycling and reuse sector involves a comprehensive supply chain. Upstream players include battery and raw material recycling companies such as CATL, BYD, Shanxi Coking, and Yunnan Tin. Midstream companies focus on refining and chemical processing, including Huayou Cobalt, New Energy Zhongneng, Ganfeng Lithium, and Haopeng Technology. Downstream firms, which manufacture battery materials or process powder metals, include Dangsheng Technology and Heyuan Fuma. This chain reflects the breadth of industrial participation in China’s growing battery recycling market.

Implications for the Future of EV Battery Technology

The U.S. findings on single-crystal battery aging and Chinese regeneration research underscore the importance of understanding material-level mechanisms and applying laboratory-scale restoration techniques to extend EV battery service life. Chinese studies demonstrate that high-nickel and LFP cathodes retain sufficient structural integrity for capacity restoration under controlled conditions. Industry analyses indicate a growing volume of end-of-life EV batteries entering the Chinese market, highlighting the need for effective recycling and regeneration solutions.

Research also identifies cost and material considerations, including cobalt usage and alternative chemistries, as relevant to potential industrial implementation of regeneration technologies. As the global demand for sustainable energy solutions increases, these advancements in battery regeneration could play a crucial role in supporting the transition to electric mobility.