MIT researchers have unveiled a groundbreaking lightweight polymer film that is nearly impenetrable to gas molecules. This innovation holds the potential to serve as a protective coating against corrosion for solar cells and infrastructure, while also slowing the aging process of packaged food and medicines. The polymer, which can be applied as a film mere nanometers thick, completely repels gases such as nitrogen, a feat previously unseen in polymers and comparable to the impermeability of materials like graphene.

The study, led by Michael Strano, the Carbon P. Dubbs Professor of Chemical Engineering at MIT, and Scott Bunch, an associate professor at Boston University, was published in the journal Nature. The research highlights the polymer’s unique ability to behave like graphene, despite being produced through a solution-phase polymerization reaction. “Our polymer is quite unusual,” Strano remarked. “It behaves like graphene, which is gas-impermeable because it’s a perfect crystal. However, when you examine this material, one would never confuse it with a perfect crystal.”

Unprecedented Gas Impermeability

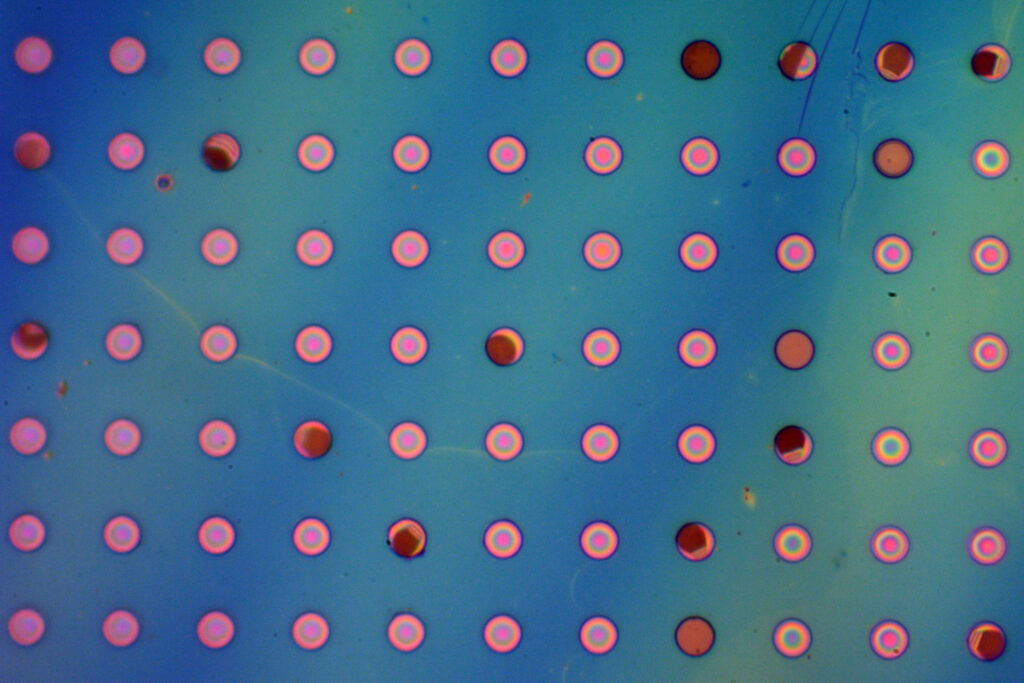

The polymer film, known as 2DPA-1, was first introduced by Strano’s lab in 2022. It is a two-dimensional polymer that self-assembles into molecular sheets using hydrogen bonds. This process, which involves the building block melamine, results in nanometer-sized disks that stack on top of each other, creating a stable and strong structure. The material is stronger than steel while possessing only one-sixth of its density.

In their initial studies, the researchers focused on the material’s strength but also noted its potential for gas impermeability. “Bubbles” made from the polymer film remained inflated, defying expectations for typical polymers. “I was quite surprised initially,” said Cody Ritt, a former MIT postdoc. “The behavior of the bubbles didn’t follow what you’d expect for a typical, permeable polymer.”

“We set up a series of careful experiments to first prove that the material is molecularly impermeable to nitrogen,” Strano explained. “It could be considered tedious work. We had to make micro-bubbles of the polymer and fill them with a pure gas like nitrogen, and then wait.”

Potential Applications and Industry Impact

The polymer’s impermeability extends beyond nitrogen. Tests showed that 2DPA-1’s permeability to gases like helium, argon, oxygen, methane, and sulfur hexafluoride is at least 1/10,000 that of any other existing polymer. This makes it nearly as impermeable as graphene, which is known for its defect-free crystalline structure.

Graphene has been pursued as a barrier to prevent corrosion in solar cells and other devices. However, scaling up graphene production is challenging due to its inability to be painted onto surfaces. In contrast, the 2DPA-1 polymer can be easily applied due to the strong hydrogen bonds between its layered disks. A 60-nanometer coating of the polymer extended the lifetime of a perovskite crystal by weeks, a significant improvement for materials used in solar cells.

“Using an impermeable coating such as this one, you could protect infrastructure such as bridges, buildings, rail lines – basically anything outside exposed to the elements,” Strano noted. “Automotive vehicles, aircraft, and ocean vessels could also benefit.”

Future Prospects and Technological Advancements

Beyond corrosion prevention, the polymer has applications in creating nanoscale resonators, which are tiny drums that vibrate at specific frequencies. These resonators, currently larger in size, are used in cell phones to pick up frequency bands. The development of smaller resonators using the 2DPA-1 polymer could revolutionize the size and power efficiency of communication devices.

“In this paper, we made the first polymer 2D resonator, which you can do with our material because it’s impermeable and quite strong, like graphene,” Strano said. “To make them less than a micron in size would be revolutionary.”

The research was supported by the Center for Enhanced Nanofluidic Transport-Phase 2, an Energy Frontier Research Center funded by the U.S. Department of Energy Office of Science, as well as the National Science Foundation. The implications of this discovery are vast, with potential applications across various industries, from electronics to infrastructure, promising a future where materials are more durable and efficient.