In a groundbreaking move, Apple has announced that all Apple Watch Ultra 3 and titanium Apple Watch Series 11 cases will now be produced using 3D-printed, 100% recycled aerospace-grade titanium powder. This innovation marks a significant shift in manufacturing practices, aligning with Apple’s commitment to sustainability and design excellence.

The announcement comes as Apple continues to push the boundaries of technology and environmental responsibility. “It wasn’t just an idea – it was an idea that wanted to become a reality,” stated Kate Bergeron, Apple’s vice president of Product Design. The company embarked on a rigorous process of prototyping and optimization to ensure the technology met their high standards.

Technological Breakthrough in Manufacturing

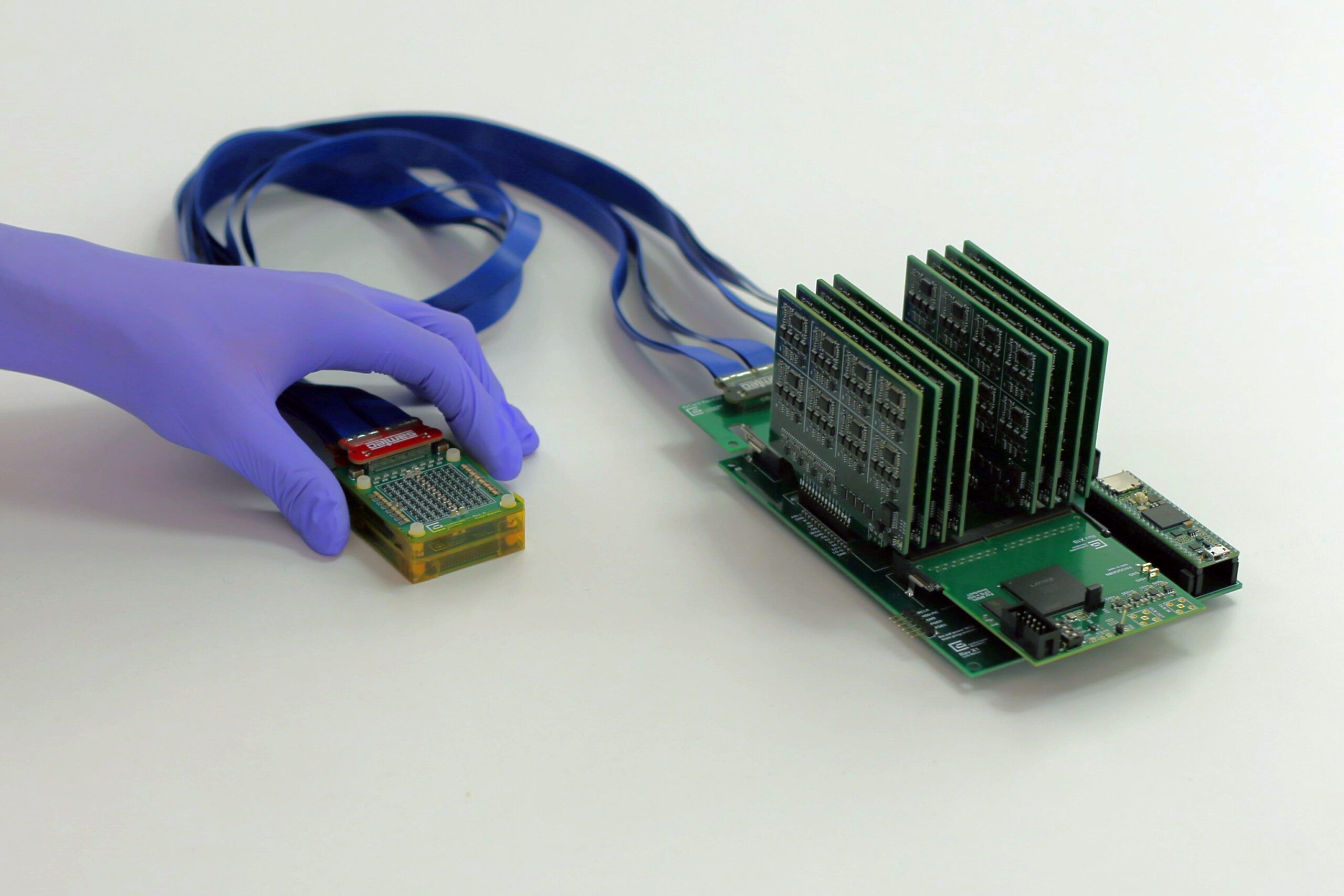

The use of 3D printing for mass production is a novel approach, especially at the scale required by Apple. Historically, 3D printing has been utilized for prototyping, but Apple’s innovation allows for the creation of millions of identical, high-quality enclosures.

“At Apple, every team holds environment as a core value,” said Sarah Chandler, Apple’s vice president of Environment and Supply Chain Innovation. The company aims to be carbon neutral across its entire footprint by 2030, a goal that includes the manufacturing supply chain and product lifecycle.

“A 50 percent drop is a massive achievement – you’re getting two watches out of the same amount of material used for one,” Chandler explains.

This efficiency is achieved through the additive process of 3D printing, which uses only half the raw material compared to traditional methods. Apple estimates that more than 400 metric tons of raw titanium will be saved this year alone due to this new process.

The Evolution of 3D Printing

Over the past decade, Apple has been at the forefront of experimenting with 3D printing. From hospital labs using 3D-printed prosthetics to astronauts creating tools aboard the International Space Station, the technology has matured significantly.

“We’ve watched this technology mature for a long time,” noted Dr. J Manjunathaiah, Apple’s senior director of Manufacturing Design for Apple Watch and Vision. The challenge was to create cosmetic parts at scale, a hurdle Apple has now overcome.

Each 3D printer used in the process is equipped with a galvanometer housing six lasers, working simultaneously to build the cases layer by layer. The process involves atomizing raw titanium into powder, fine-tuning its oxygen content to reduce explosiveness when exposed to heat.

Environmental and Design Implications

Apple’s commitment to environmental sustainability is evident in its approach to design and manufacturing. The shift to 3D printing not only reduces material waste but also opens up new possibilities for design flexibility.

“We’re extraordinarily committed to systems change,” Chandler emphasized. “Our North Star has always been to design products that are better for people and planet.”

This breakthrough in 3D printing has also influenced other Apple products, such as the USB-C port on the new iPhone Air, which features a 3D-printed titanium enclosure.

As Apple continues to innovate, the implications of this technological advancement are far-reaching. The company’s ability to align design, manufacturing, and environmental goals demonstrates a model for sustainable innovation that could influence the entire industry.

Looking forward, Apple’s success with 3D printing sets a precedent for future product development, potentially revolutionizing how consumer electronics are manufactured worldwide.