Apple has unveiled a groundbreaking shift in its manufacturing process by utilizing 3D-printed titanium cases for its Apple Watch Ultra 3 and Series 11 models. This innovative approach, announced this year, marks a significant leap in Apple’s commitment to sustainability and advanced manufacturing techniques.

The initiative began as a visionary idea: leveraging 3D printing, traditionally used for prototypes, to mass-produce high-quality enclosures from recycled metal. According to Kate Bergeron, Apple’s vice president of Product Design, the idea quickly transitioned from concept to reality through rigorous testing and process optimization. “It wasn’t just an idea – it was an idea that wanted to become a reality,” Bergeron stated.

Revolutionizing Manufacturing with 3D Printing

The adoption of 3D printing for these watch cases signifies a major advancement in material efficiency. The cases are crafted from 100 percent recycled aerospace-grade titanium powder, a feat previously deemed unachievable at scale. This method not only ensures high-quality finishes but also aligns with Apple’s environmental goals.

Sarah Chandler, Apple’s vice president of Environment and Supply Chain Innovation, emphasized the potential of 3D printing for material efficiency, a critical component of Apple’s 2030 carbon neutrality goal. “We knew 3D-printing was a technology with so much potential for material efficiency, which is critical for getting to Apple 2030,” Chandler explained.

Environmental and Material Benefits

The 3D printing process allows Apple to use just half the raw material compared to previous generations, resulting in significant environmental savings. “A 50 percent drop is a massive achievement,” Chandler noted. “When you start mapping that back, the savings to the planet are tremendous.”

Apple estimates that more than 400 metric tons of raw titanium will be saved this year alone thanks to this new process.

This transition to additive manufacturing represents a broader trend within the tech industry, where companies are exploring innovative ways to reduce their carbon footprints. Apple’s commitment to renewable energy in its manufacturing processes further underscores this shift.

Technological and Design Innovations

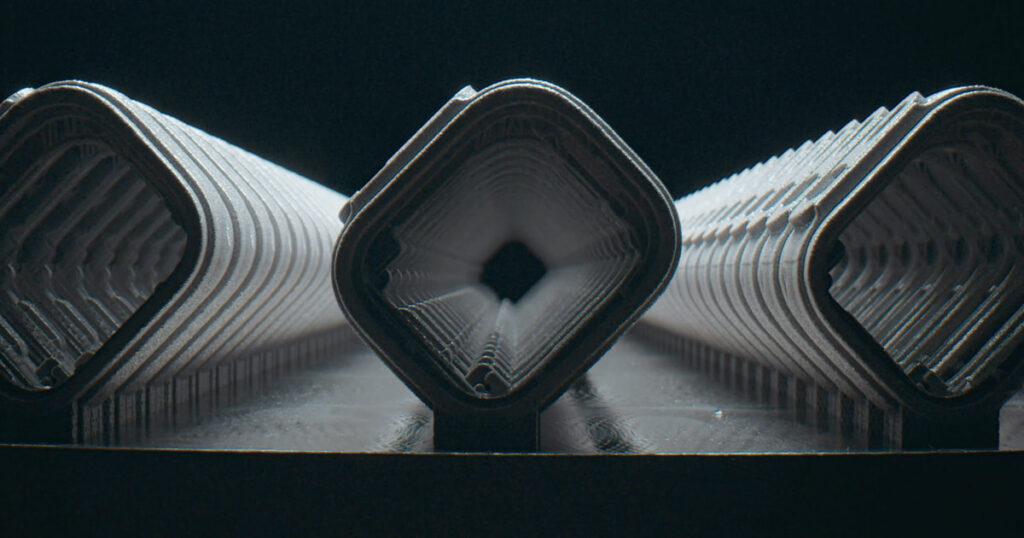

Historically, machining parts has been a subtractive process, requiring significant material waste. In contrast, 3D printing builds objects layer by layer, minimizing waste and optimizing material use. This technological shift is part of a broader industry trend, with applications ranging from medical prosthetics to aerospace tools.

Dr. J Manjunathaiah, Apple’s senior director of Manufacturing Design for Apple Watch and Vision, highlighted the challenges and breakthroughs in using 3D printing for cosmetic parts. “Using less material to make our products has always been the intention,” he said. “Previously, we hadn’t been able to make cosmetic parts at scale with 3D printing.”

Precision and Quality Assurance

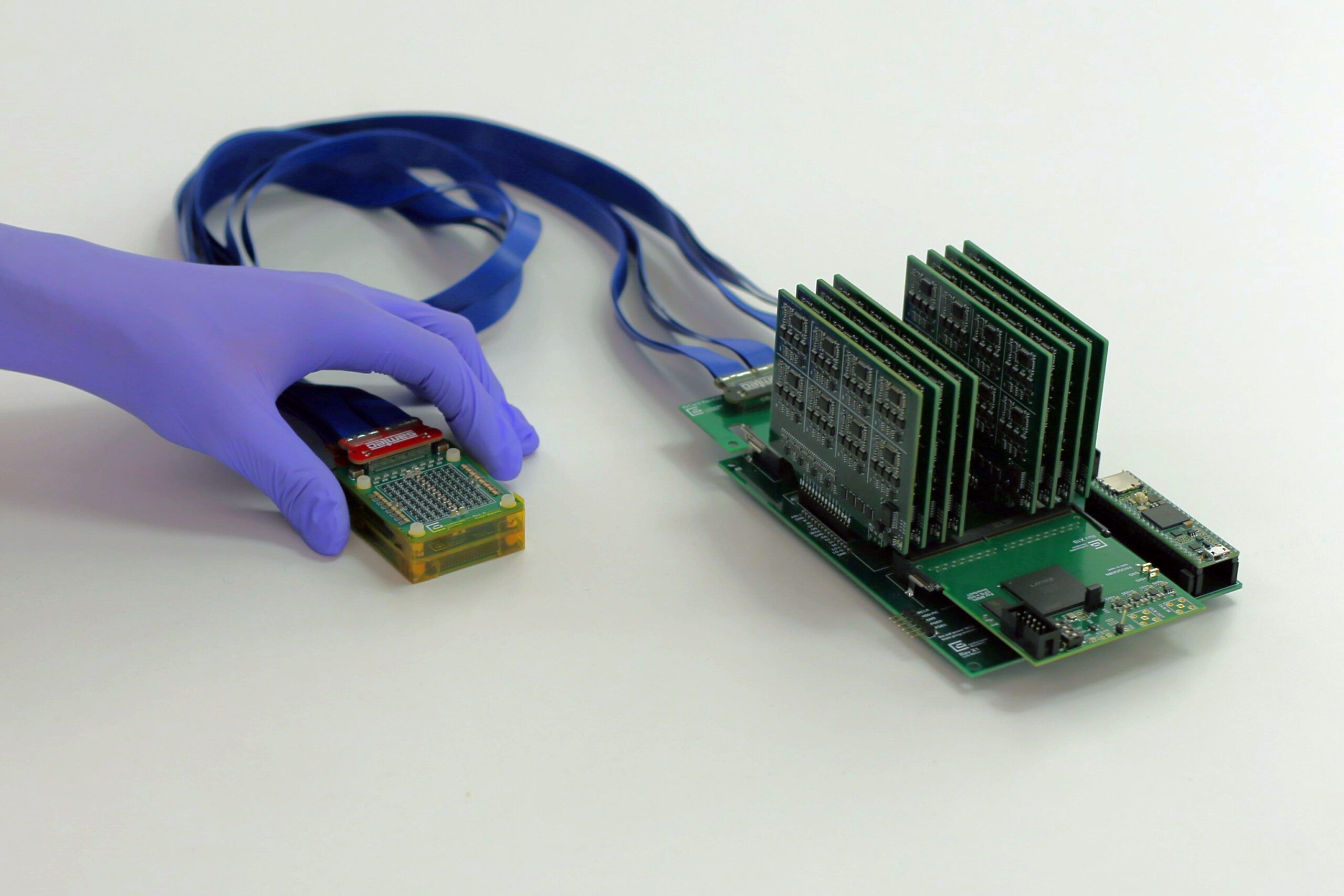

The 3D printing process involves intricate steps to ensure precision and quality. Each machine uses six lasers to build the cases layer by layer, while the titanium powder is carefully prepared to prevent any explosive reactions when exposed to heat. “This was cutting-edge materials science,” Bergeron remarked.

Once printed, the cases undergo a series of quality checks to ensure they meet Apple’s stringent standards. This includes rough and fine depowdering, singulation, and automated optical inspections to verify dimensions and aesthetics.

Future Implications and Innovations

The successful implementation of 3D-printed titanium cases opens new possibilities for Apple’s product design and manufacturing processes. This technology not only enhances the durability and aesthetics of the Apple Watch but also extends to other products, such as the USB-C port on the new iPhone Air.

Chandler emphasized Apple’s long-term commitment to sustainable innovation. “We’re extraordinarily committed to systems change,” she said. “Our North Star has always been to design products that are better for people and planet.”

As Apple continues to explore the potential of 3D printing and other advanced manufacturing techniques, the company sets a precedent for the tech industry, demonstrating that sustainability and innovation can go hand in hand.