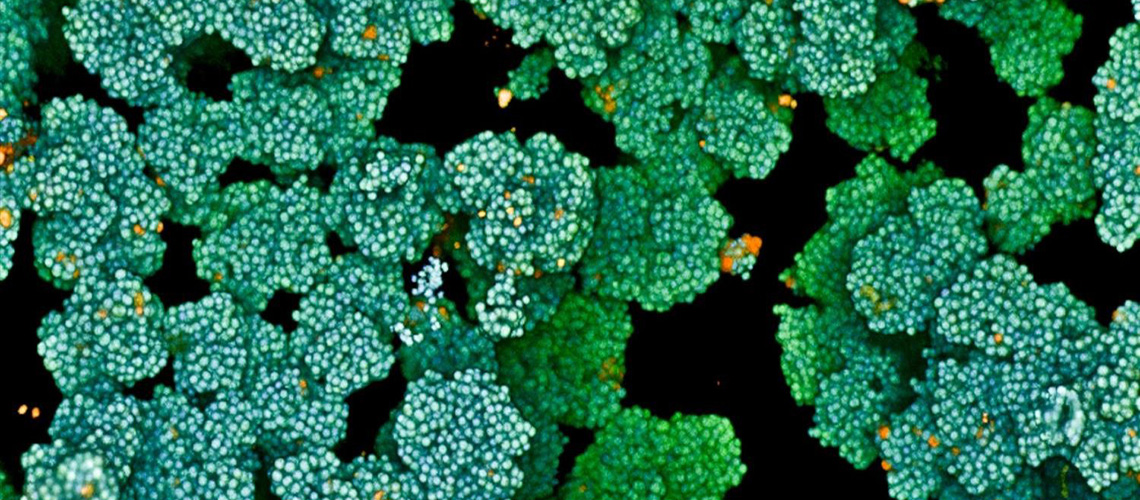

One of Western Australia’s largest meat processors, V&V Walsh, has embraced artificial intelligence to enhance the accuracy of livestock counting at its Bunbury abattoir, located 150 kilometers south of Perth. The facility processes over a million sheep and cattle annually, and the introduction of AI technology is proving to be a game-changer.

V&V Walsh, a major employer in the South West region with approximately 650 staff, assures that the deployment of AI has not led to any job losses. According to General Manager Brent Dancer, the technology is significantly transforming the sheep delivery process. “We’ve now got the ability to cross-reference an AI camera count versus a manual count versus the numbers going across our scales,” he explained.

Enhancing Accuracy and Trust

The implementation of AI at V&V Walsh provides multiple data points for cross-referencing, ensuring precise livestock counts. This accuracy is crucial for both processors and farmers, as Mr. Dancer noted, “You’re talking a couple of hundred dollars a head for a good sheep, thousands of dollars for a good cattle.”

Accurate counts ensure that producers are fairly compensated, as discrepancies between paperwork and actual deliveries can occur. “We always pay off the count of physical through the floor,” Dancer emphasized, highlighting the importance of trust and transparency in transactions with farmers.

Industry-Wide Adoption on the Horizon

The success of AI at V&V Walsh could herald broader adoption across the livestock industry. Mr. Dancer anticipates that the seamless integration of this technology will prompt others nationwide to follow suit. “I suspect across the country, people are going to start to really look at this sort of technology to assist with the process because livestock is getting more and more expensive,” he stated.

The AI cameras have also alleviated a longstanding burden for workers tasked with counting large numbers of sheep. “It’s obviously been a pain point in the industry for some time — the dread of having to count 1,000 sheep off a truck coming forward at a time,” Dancer remarked. The technology not only improves accuracy but also reduces the physical and mental strain on staff.

Impact on Employment and Efficiency

While AI technology has not reduced the workforce, it has shifted the nature of work at the abattoir. Plant Manager Darren Brady noted that staff were initially apprehensive but have since embraced the new system. “If we are questioned in any way, shape or form, we can go back to the footage and review it,” he said, underscoring the reliability and accuracy of AI.

Brady also sees AI as an opportunity to boost employment by increasing operational efficiency. “We’ve got plans to grow the business, so with a more efficient room, putting more and more technology in,” he explained. Despite current employment challenges, Brady believes that technological advancements will eventually create more jobs at V&V Walsh.

Looking Ahead

The integration of AI technology at V&V Walsh represents a significant step forward in the livestock processing industry. As the company continues to innovate and expand, it sets a precedent for others in the sector to leverage technology for enhanced accuracy and efficiency. With livestock prices on the rise, the precision offered by AI could become indispensable for processors and producers alike.

As the industry watches closely, the successful implementation at V&V Walsh could serve as a model for others looking to modernize their operations. The move towards AI not only promises to streamline processes but also to foster a more transparent and trustworthy relationship between processors and farmers.