Swinburne University of Technology and CSIRO researchers have successfully produced iron under Mars-like conditions, marking a significant breakthrough in the quest for off-world metal production. This innovative process could pave the way for building sustainable settlements on Mars, a popular goal among billionaires, space agencies, and interplanetary enthusiasts.

The challenge of constructing infrastructure on Mars is daunting due to the prohibitive costs of transporting materials from Earth. For instance, NASA’s one-ton Perseverance Rover cost a staggering $243 million to send to the Red Planet. As Dr. Deddy Nababan, a CSIRO Postdoctoral Fellow and Swinburne alum, points out, “Sending metals to Mars from Earth might be feasible, but it’s not economical.”

Unlocking the Potential of Martian Regolith

Dr. Nababan’s solution lies in the Martian soil, known as regolith. This concept, called in-situ resource utilization (ISRU), involves using materials available on Mars to produce necessary resources. More specifically, Dr. Nababan is exploring astrometallurgy, the process of making metals in space.

Mars possesses the essential ingredients needed for metal production, including iron-rich oxides in regolith and carbon from its atmosphere, which acts as a reducing agent. Swinburne’s astrometallurgist, Professor Akbar Rhamdhani, collaborates with Dr. Nababan to test this process using regolith simulant, an artificial recreation of Martian soil.

Simulating Martian Conditions

The researchers employed a regolith simulant that mimics the materials found at Gale Crater on Mars. “We picked a simulant with very similar properties to that found at Gale Crater on Mars and processed them on Earth with simulated Mars conditions to give us a good idea of how the process would perform off-world,” Professor Rhamdhani explained.

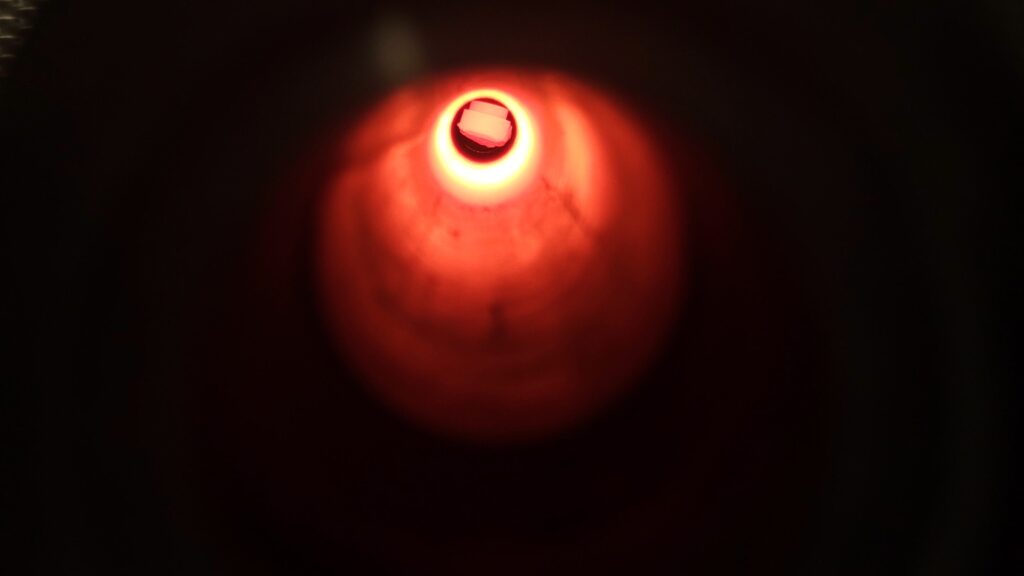

In their experiments, the simulant was placed inside a chamber at Mars surface pressure and heated to increasing temperatures. The results were promising, with pure iron metal forming around 1,000°C and liquid iron-silicon alloys produced at approximately 1,400°C.

“At high enough temperatures, all of the metals coalesced into one large droplet. This could then be separated from liquid slag the same way it is on Earth,” Professor Rhamdhani said.

Advancing Space Science with ISRU

The concept of ISRU is gaining traction in space science, especially as the cost of rocket launches decreases while the demands of human exploration increase. A notable development in this area is the MOXIE experiment aboard the Mars Perseverance rover, which successfully produced breathable oxygen from the planet’s carbon dioxide-rich atmosphere.

Metal production represents the next significant leap forward. Professor Rhamdhani envisions Mars-made alloys being used for constructing housing shells, research facilities, and machinery for excavation. However, challenges remain, such as understanding how these alloys would perform over time and whether the process can be replicated on Mars itself.

Meanwhile, Swinburne and its partners are committed to advancing this research. Professor Rhamdhani, along with Dr. Matt Shaw and Dr. Nababan, recently conducted a four-day workshop on astrometallurgy in South Korea, receiving positive feedback.

“We’re starting to see increased interest in this field globally as the world gets serious about Mars exploration,” Professor Rhamdhani noted. “To make it happen, we’re going to need experts from many fields—mining, engineering, geology, and much more.”

Implications for Earth and Beyond

For Dr. Nababan, the benefits of this research extend beyond space exploration. He hopes their work will lead to more efficient metallurgy practices on Earth, ultimately benefiting human life. “By doing this, I wish that I can help the development of space exploration, and at the end it will bring good to human life here on Earth,” he expressed.

As the world continues to explore the possibilities of Mars colonization, the work of these researchers represents a crucial step forward. With ongoing advancements in ISRU and astrometallurgy, the dream of sustainable off-world settlements is becoming increasingly tangible.

For more information, readers can refer to the published papers by Deddy C. Nababan et al. in the journal Acta Astronautica, detailing the thermodynamic assessment and experimental study of iron extraction on Mars.