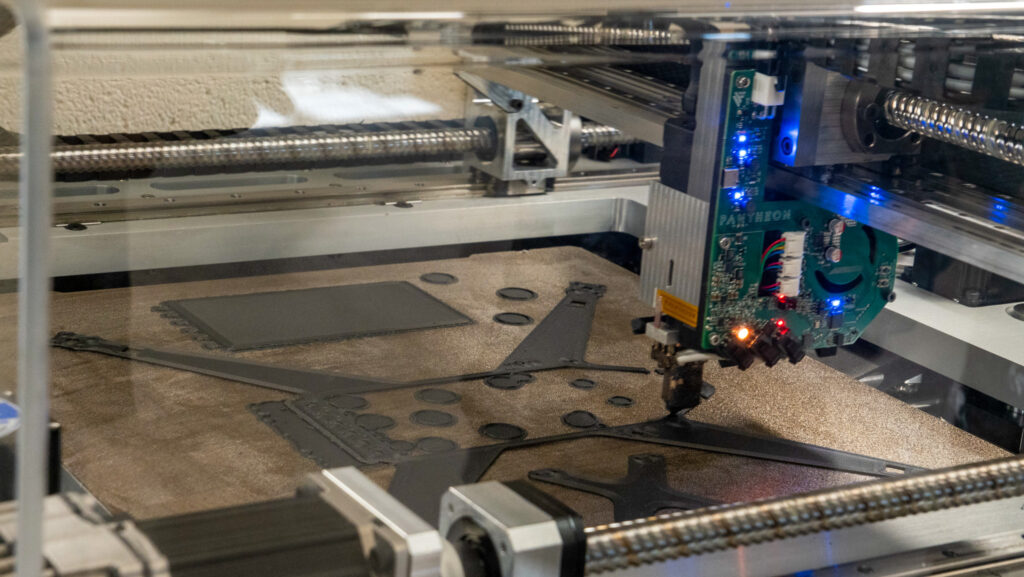

The US Army is poised to significantly expand its use of 3D printing technology, as highlighted by several officials at the Ground Vehicle Systems Engineering and Technology Symposium (GVSETS) 2025. The military branch aims to leverage the advantages of additive manufacturing to enhance logistics and sustainment operations.

Randl Besse, a commodity manager at the Rock Island Arsenal Joint Manufacturing and Technology Center, emphasized the rapid progress in this field during a session at the conference.

“Just like everything else with technology, it is kind of a crawl, walk, run. I would say [with additive manufacturing] we are in the walking stage, but we are going to be running very, very soon,”

Besse stated. Currently, over 1,500 different components for various Army platforms have been produced using 3D printing at the facility.

Advancing Beyond Repair Fabrication

Jason Duncan, maintenance integration division chief at the Integrated Logistics Support Center of the Tank-Automotive & Armaments Command, outlined the Army’s goal to transition from using 3D printing solely for battle damage repair to a fully qualified production approach.

“We have been coordinating to be able to move faster and make sure we have a good process. That cutting-edge technology allows us to kind of move at the pace of change,”

Duncan remarked.

This development follows a broader trend in military technology, where agility and adaptability are increasingly prioritized. The Army is not limiting its additive manufacturing ambitions to land vehicles. In response to the global race to enhance unmanned aerial systems, the Army is exploring the use of 3D printing to manufacture drone bodies at a scale of 10,000 per month, according to Besse.

Industry Collaboration and Future Capabilities

The Army’s commitment to expanding its 3D printing capabilities includes plans to acquire new technologies. Brandon Pender, associate director of the Ground Vehicle Materials Engineering at the Combat Capabilities Development Command Ground Vehicle Systems Center, invited industry collaboration to advance these efforts.

“We are open to doing our cooperative R&D agreements with any of you in the room, and happy to discuss what you could print for us. Additionally, we have our laboratories available. We have our machines available,”

Pender said.

Suppliers can engage with the Army to have prototypes printed and tested, even in large forms using materials like aluminum and other alloys. This initiative represents a significant opportunity for industry partners to contribute to military innovation.

Ensuring Quality and Supply Chain Resilience

As the Army scales its 3D printing operations, it is also focusing on establishing guidelines for certifying printed parts. Pender highlighted the importance of creating a “digital ID” for each component, which could revolutionize supply chain management by eliminating obsolescence issues.

“If we have a digital recipe, we don’t have to worry about tooling, if there is a vendor to qualify. We should be thinking about how to digitally validate parts,”

Pender explained.

This move represents a strategic shift in how the Army approaches logistics and manufacturing, potentially setting a precedent for other military branches and industries. By embracing digital validation, the Army could ensure a more resilient and adaptable supply chain, ready to meet the demands of modern warfare.

Meanwhile, the broader implications of this technological advancement could extend beyond military applications. As 3D printing technology matures, its potential to transform industries such as aerospace, automotive, and healthcare becomes increasingly apparent. The Army’s proactive stance could serve as a catalyst for wider adoption and innovation in these sectors.

Looking ahead, the Army’s continued investment in 3D printing technology is expected to enhance its operational capabilities and readiness. As the technology progresses from the “walking” to the “running” stage, the potential for transformative impacts on military logistics and beyond is substantial.