UNIVERSITY PARK, Pa. — In a groundbreaking development, researchers at Penn State University have unveiled a new type of smart synthetic skin, inspired by the adaptive capabilities of octopus skin. This innovative material, spearheaded by Hongtao Sun, assistant professor of industrial and manufacturing engineering, promises to revolutionize various fields by offering multifunctional capabilities such as adaptive camouflage, information encryption, and powering soft robotics.

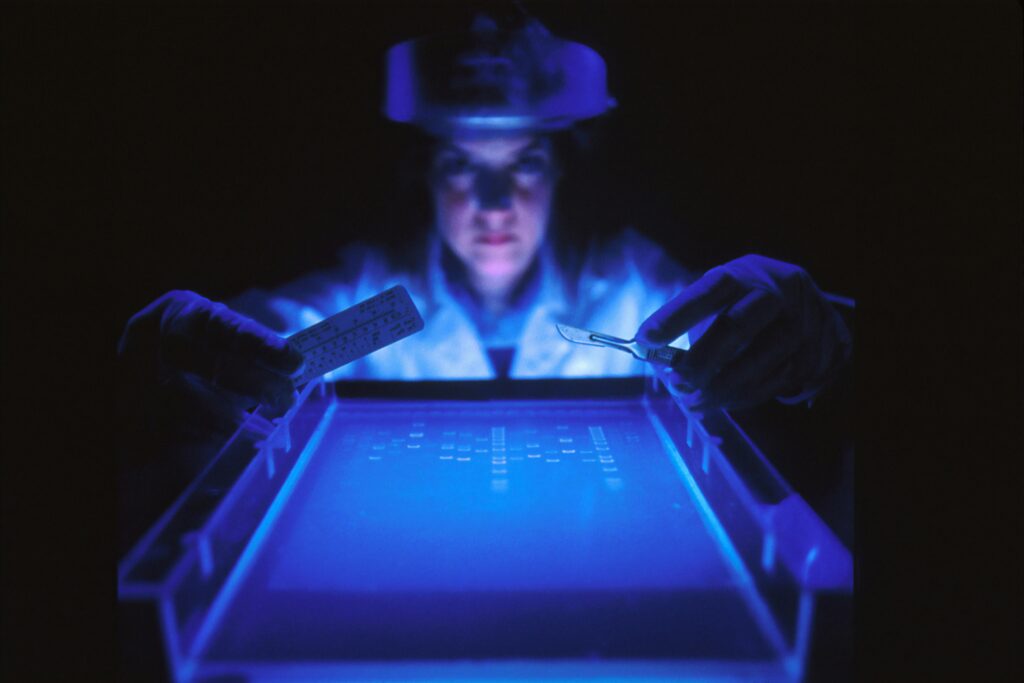

The research team has devised a novel fabrication method that allows for the printing of this smart skin using hydrogel, a water-rich, gel-like substance. Unlike traditional synthetic materials, which are often limited to specific functions, this smart skin can dynamically alter its optical, mechanical, and textural properties in response to external stimuli like heat, solvents, or mechanical stress.

Inspired by Nature’s Master of Disguise

The concept behind this innovative material draws inspiration from cephalopods, such as octopuses, which are known for their ability to change skin texture and color to blend into their surroundings or communicate. “Cephalopods use a complex system of muscles and nerves to exhibit dynamic control over the appearance and texture of their skin,” Sun explained. “Inspired by these soft organisms, we developed a 4D-printing system to capture that idea in a synthetic, soft material.”

This 4D-printing approach involves creating three-dimensional objects that can adjust reactively to environmental changes. The team employed a technique known as halftone-encoded printing, which encodes digital information into the material using binary patterns, similar to the dot patterns used in newspapers or photographs. This allows the smart skin to change its appearance or texture when exposed to various stimuli.

Technological Advancements and Demonstrations

One of the most striking demonstrations of this technology is its ability to hide and reveal information. Haoqing Yang, a doctoral candidate and first author of the paper, described how the team encoded a photo of the Mona Lisa onto the smart skin. Initially invisible, the image becomes apparent when the material is exposed to specific conditions, such as immersion in ice water or gradual heating.

“This behavior could be used for camouflage, where a surface blends into its environment, or for information encryption, where messages are hidden and only revealed under specific conditions,” Yang stated. Furthermore, the material’s malleability allows it to transform from a flat sheet into complex, bio-inspired shapes without requiring multiple layers or different materials.

“In simple terms, we’re printing instructions into the material,” Sun explained. “Those instructions tell the skin how to react when something changes around it.”

Applications and Future Prospects

The potential applications for this smart skin are vast. By co-designing the halftone patterns, the researchers demonstrated that the material could simultaneously control shape and appearance. For instance, as flat sheets curve into dome-like structures, hidden images gradually become visible, showcasing the material’s ability to coordinate changes in shape and appearance.

This research builds on previous efforts to 4D-print smart hydrogels, where the focus was on co-designing mechanical properties and programmable shape morphing. The current advancement introduces a halftone-encoded 4D printing method to integrate more functions within a single smart hydrogel film.

Looking ahead, the team aims to develop a scalable platform that enables precise digital encoding of multiple functions into a single adaptive smart material system. “This interdisciplinary research at the intersection of advanced manufacturing, intelligent materials, and mechanics opens new opportunities with broad implications for stimulus-responsive systems, biomimetic engineering, advanced encryption technologies, biomedical devices, and more,” Sun remarked.

Collaborative Efforts and Broader Implications

The project, which was detailed in a paper published in Nature Communications and featured in Editors’ Highlights, involved contributions from other Penn State researchers, including Haotian Li and Juchen Zhang, doctoral candidates in IME, and Tengxiao Liu, a lecturer in biomedical engineering. H. Jerry Qi, a professor of mechanical engineering at Georgia Institute of Technology, also collaborated on the work.

The development of this smart material represents a significant leap forward in the field of intelligent materials, offering a glimpse into a future where materials can adapt and respond to their environments in sophisticated ways. As the research progresses, it holds the promise of transforming industries ranging from defense and security to healthcare and consumer electronics.