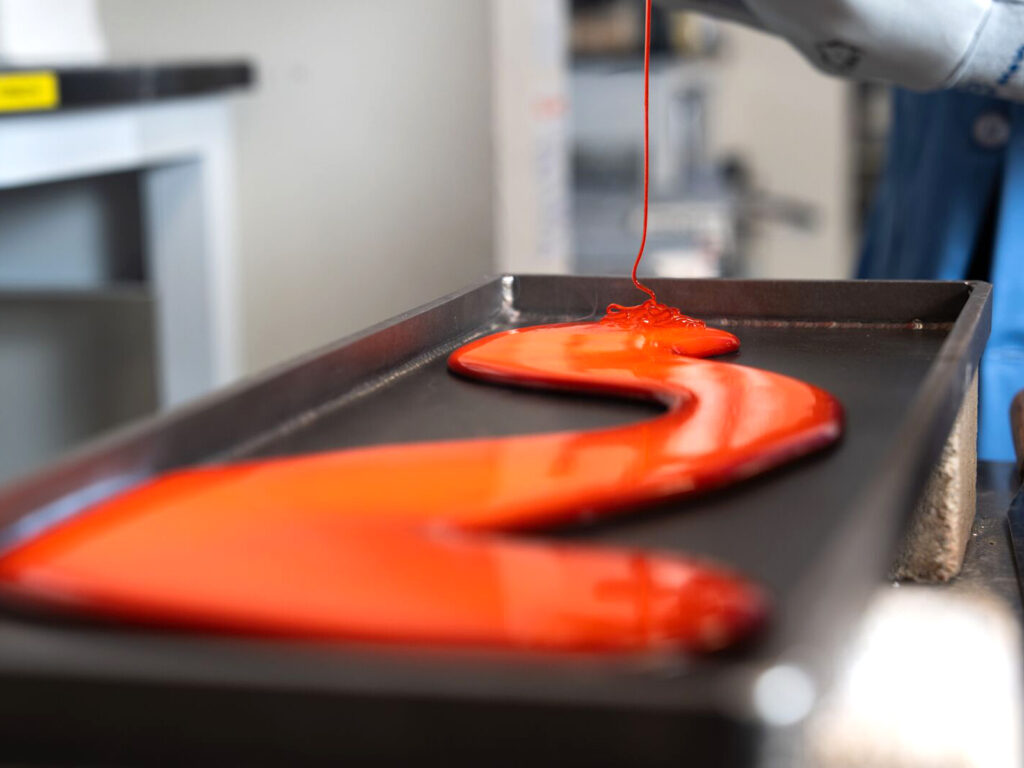

RICHLAND, Wash. — In a groundbreaking achievement decades in the making, scientists at the Hanford Site have begun converting low-activity radioactive waste into glass, a process known as vitrification. This historic event marks the successful launch of Hanford’s Waste Treatment and Immobilization Plant, commonly referred to as the “Vit Plant,” which aims to transform millions of gallons of waste from the Manhattan Project and Cold War into glass for safe, long-term storage.

The milestone represents nearly 60 years of scientific contributions from the Department of Energy’s Pacific Northwest National Laboratory (PNNL). “PNNL is proud to have played a pivotal role in advancing modern vitrification technology,” said Deb Gracio, PNNL director. “This milestone underscores the importance of innovation, collaboration, and scientific excellence in solving some of the world’s most pressing problems.”

The Birth of Vitrification Technology

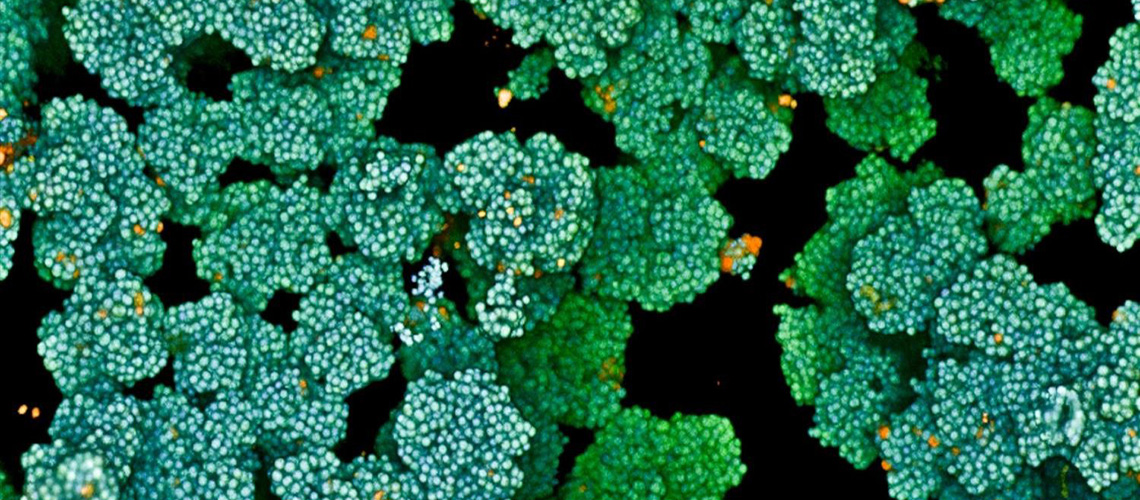

The development of vitrification technology has been a persistent focus for PNNL researchers since the 1960s. Among their most significant contributions is the liquid-fed ceramic melter, a technology now used globally for nuclear waste vitrification. This melter operates at temperatures reaching 2,100°F, where waste is mixed with glass-forming chemicals and converted into glass.

Each of the Hanford Site’s 177 tanks contains a unique chemical composition, making the vitrification process complex. The “right” glass must immobilize as much waste as possible while remaining durable and safe for transport. Historically, designing such glass required extensive testing and fine-tuning.

Innovations in Glass Design

John Vienna, a PNNL materials scientist, highlighted the challenges of vitrifying Hanford’s chemically complex waste. To address these challenges, Vienna and his team developed a computational approach that uses modeling to predict glass recipes. This method has significantly reduced the time and cost associated with glass design.

By utilizing computer models trained on historical data, the team can generate glass recipes in less than 120 minutes, a process that once took years. “For the Vit Plant to operate successfully, we had to make it so that process happened on the order of minutes,” Vienna explained.

Global Impact and Future Prospects

The innovations at Hanford have not only advanced local operations but have also informed vitrification efforts worldwide. The computational approach has saved years of effort and millions of dollars at other sites, such as the DOE’s Savannah River Site in South Carolina.

PNNL’s contributions extend beyond glass design. The lab has developed key equipment for the Vit Plant, including the submerged bed scrubber and air displacement slurry pump. These innovations enable each melter to produce up to 15 metric tons of glass per day.

“PNNL has been an integral part of the Hanford Waste Treatment and Immobilization Plant,” said Chris Musick, general manager of the Bechtel-led Waste Treatment Completion Company LLC. “We look forward to growing our partnership with PNNL in the future.”

Looking Ahead: The Next Generation

As vitrification at Hanford begins, PNNL scientists continue to support the plant by analyzing waste and providing rapid solutions during start-up. Materials scientist José Marcial, who began his career with a PNNL internship, expressed excitement about the project’s progress. “It’s extremely exciting,” Marcial said. “This shows that this isn’t just an academic exercise. It’s all of our effort being put to real use to benefit the country and our community.”

While the vitrification process has started, much work remains. Marcial and his team are focused on improving efficiency and addressing operational challenges. PNNL researchers are also contributing to broader cleanup efforts, including waste form development and environmental remediation.

Looking to the future, Marcial emphasized the importance of nurturing the next generation of scientists. “I think it’s important to always bring up the next generation of scientists so they, too, can help to solve challenges for the benefit of the country,” he said.