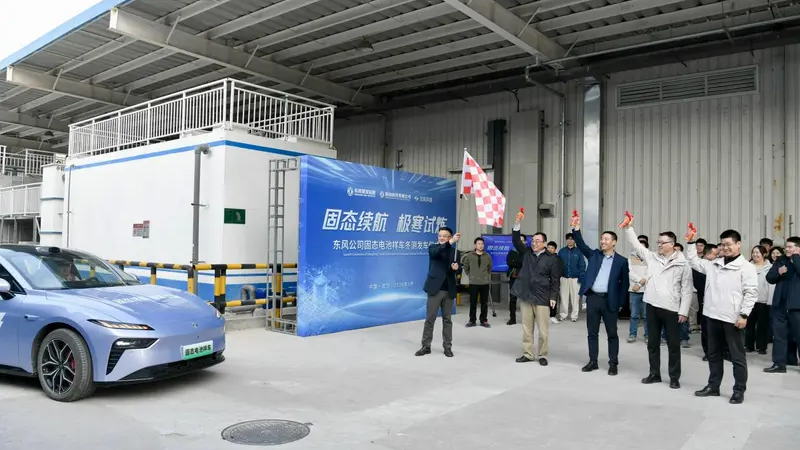

Dongfeng Automobile has taken a significant step forward in battery technology by dispatching test vehicles equipped with their new 350Wh/kg solid-state batteries for extreme cold weather testing. The announcement, made by Yipai Technology, marks the beginning of a rigorous testing phase as the fleet departs from Wuhan to the Mohe Cold Region, located in China’s northernmost area, to undergo winter calibration.

The 350Wh/kg solid-state battery represents a major advancement for Dongfeng. These batteries are designed to support vehicle ranges exceeding 1,000 kilometers on a single charge. Notably, they have passed stringent 170°C heat box tests and maintain 72% energy retention at temperatures as low as -30°C, showcasing their resilience in extreme conditions.

Testing and Technological Advancements

The current testing program aims to evaluate the batteries across three core dimensions: low-temperature range, low-temperature charging capability, and low-temperature durability. More than 70 tests will be conducted in conditions ranging from -40°C to -30°C to assess metrics such as range stability, charging and discharging efficiency, structural safety, and overall vehicle integration.

Dongfeng has developed a comprehensive platform that covers the entire “R&D-trial production-pilot testing” process. The company has reportedly overcome over 10 key core technologies and applied for more than 180 invention patents. Their battery development roadmap includes products with energy densities ranging from 240Wh/kg to 500Wh/kg.

Showcasing at the World Power Battery Conference

At the 2025 World Power Battery Conference in Yibin, Sichuan, Dongfeng showcased its next-generation solid-state battery products and several new energy vehicle models. The company has already built and commissioned a 0.2GWh solid-state battery pilot production line, with plans to begin mass production of the 350Wh/kg batteries by September 2026. The charging rate for these batteries is 1C, according to Dongfeng representatives at the conference.

According to Chinese media Hubei Daily, the solid-state batteries utilize high-capacity ternary cathodes, silicon-carbon anodes, and oxide-polymer composite solid-state electrolyte systems, addressing the safety and low-temperature performance shortcomings of traditional lithium batteries.

Breakthroughs and Challenges in Solid-State Battery Development

Recent breakthroughs by Chinese research teams have been pivotal in overcoming technical barriers in solid-state battery development. Innovations include iodine ion additives from the Institute of Physics of the Chinese Academy of Sciences, polymer frameworks from the Institute of Metals, and fluorine-containing polyether materials from Tsinghua University, which enhance flexibility and high-pressure resistance.

Despite these advancements, solid-state batteries are still in their nascent stages. Battery industry giant CATL estimates it will take another three to five years for the technology to fully mature. Current development faces limitations such as rapid volume expansion and toxic gas release, making them largely unsuitable for on-road testing.

Future Prospects and Industry Implications

To achieve road-test capability, compromises are necessary. Dongfeng’s latest product reflects this with its 350 Wh/kg energy density and 1C charging speed, which are moderate by industry standards. However, these trade-offs have enabled the product to proceed with road testing, marking a significant milestone in the transition from laboratory to real-world applications.

As the industry continues to innovate, the potential for solid-state batteries to revolutionize electric vehicles remains high. The ongoing tests in Mohe will provide critical data that could influence future developments and accelerate the adoption of this promising technology.