AUSTIN, Texas — In a significant breakthrough, researchers have pinpointed a crucial factor contributing to the deterioration of batteries that power devices ranging from smartphones to electric vehicles. This discovery marks a pivotal step toward engineering faster, more reliable, and longer-lasting batteries.

The research, conducted by a team from The University of Texas at Austin, Northeastern University, Stanford University, and Argonne National Laboratory, reveals that each cycle of charging and discharging causes batteries to expand and contract, akin to human breathing. This repeated action results in minor warping of battery components, exerting strain and ultimately weakening the battery over time. This process, termed “chemomechanical degradation,” significantly diminishes battery performance and lifespan.

Unraveling the Mystery of Battery Degradation

The findings provide new insights into a problem that has long puzzled scientists and engineers worldwide. “With every ‘breath’ of the battery, there’s some degree of irreversibility,” explained Yijin Liu, an associate professor in the Cockrell School of Engineering’s Walker Department of Mechanical Engineering and Texas Materials Institute. Liu led the study, which was published in the journal Science. “This effect accumulates over time, eventually causing failure of the cell,” he added.

A key discovery was the identification of “strain cascades” — a chain reaction where stress accumulates in one part of the electrode and propagates to adjacent areas. The unpredictable behavior of the hundreds of thousands of particles within batteries contributes to this strain.

The Role of Particle Dynamics

“We were able to see that every particle behaves differently under electrochemical stress,” noted Juner Zhu, assistant professor of mechanical and industrial engineering at Northeastern and a co-author of the study. “Some particles move rapidly, like shooting stars in the sky, while others remain relatively stable. This uneven behavior creates localized stress that can lead to cracks and other damage.”

By comprehending how strain develops and spreads, engineers can design electrodes that better resist stress and degradation. For instance, the study suggests that applying controlled pressure to battery cells could help alleviate strain and enhance performance.

Implications for Future Battery Technology

“Our ultimate goal is the creation of advanced technologies that can substantially increase the utility and durability of batteries,” stated Jason Croy, co-author and group leader for the Materials Research Group at Argonne National Laboratory. “Understanding how the design of electrodes influences their response to stress is a critical step in pushing the boundaries of what batteries can do.”

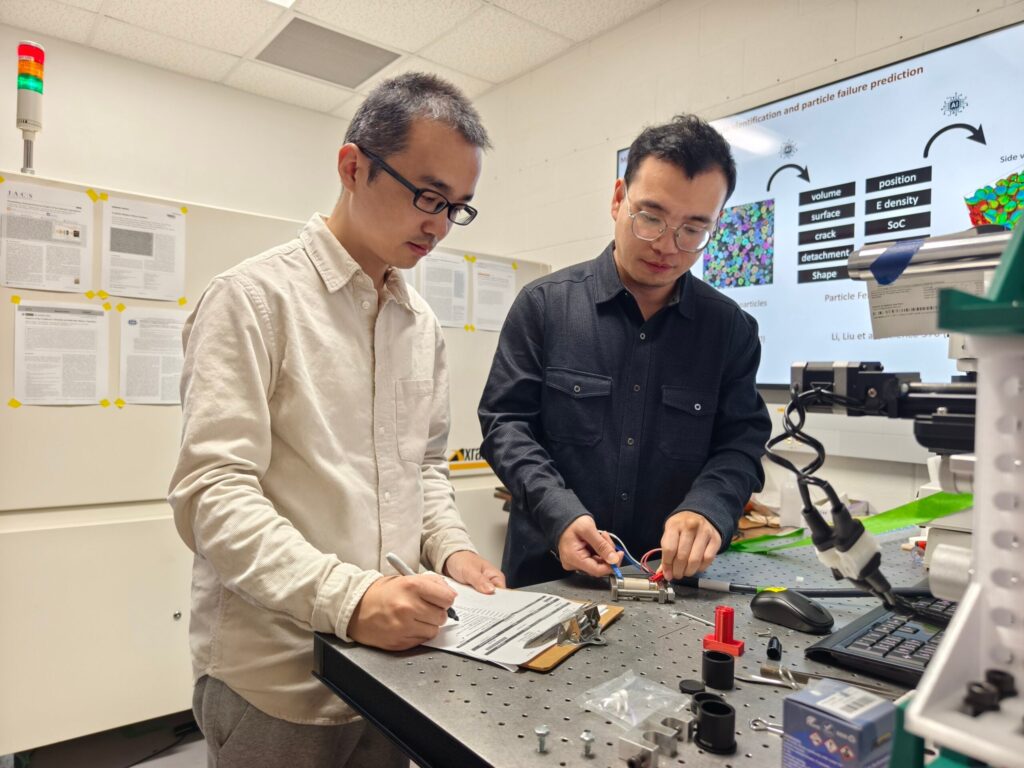

To unearth this new information, the research team utilized advanced imaging techniques to observe battery electrodes in real-time during charging and discharging. Employing cutting-edge tools such as operando transmission X-ray microscopy (TXM) and 3D X-ray laminography, they captured detailed images of particle movements and interactions within the electrodes.

Future Directions and Continued Research

The researchers initially observed this dynamic in a device used for another research project, commercial earbuds. The team plans to continue along this path, with the next step focusing on developing theoretical models to further understand the complex interactions between chemical and mechanical processes in battery electrodes.

The research received funding from the U.S. Department of Energy’s Vehicle Technologies Office. Other team members include Tianxiao Sun, Guannan Qian, Wenlong Li, Shimao Deng, and professor Guihua Yu of UT’s Materials Science and Engineering Program and mechanical engineering department; Ruqing Fang of Northeastern University; Guibin Zan and Wenbing Yun of Sigray Inc.; Zhichen Xue, professors Will Chueh and Piero Pianetta of Stanford and SLAC National Accelerator Laboratory; and Stephen E. Trask, Arturo Gutierrez, and Luxi Li of Argonne National Laboratory.

As the research progresses, the potential for developing more resilient battery technologies could revolutionize industries reliant on battery power, from consumer electronics to electric vehicles, offering a glimpse into a future where battery lifespan is no longer a limiting factor.