Chemical reactions sensitive to force could revolutionize engineered materials, enabling them to mimic the lifelike motions of living tissue. This breakthrough holds potential for advancements in robotics and other cutting-edge technologies. Researchers at the University of Michigan have developed a theoretical framework to achieve this, as detailed in their recent publication in Physical Review Letters.

When considering high-powered machines, muscle cars might come to mind before human muscles. Yet, muscles and other living tissues perform energetic actions rapidly, such as twitching, snapping, and beating—an embodiment of power as defined by physics. Inspired by biology, scientists and engineers have long sought to create soft, elastic, and lightweight materials for various applications, including engines and robotic devices. However, these synthetic materials have struggled to replicate the dynamic capabilities of living tissue.

Innovative Framework for Synthetic Motion

The new model proposed by the University of Michigan team provides a pathway to overcome these limitations. “Our interest was to think about fast movements,” explained Suraj Shankar, an assistant professor of physics at U-M. “If we want to make soft engines and soft machines that pack a punch and can drive extremely fast motions, that’s a really difficult task.”

Shankar and his colleagues demonstrated that the challenge could be addressed by integrating a material’s internal mechanics with its chemistry. This approach transforms the material’s innate resistance to motion into an enabling feature. The research received support from the U.S. National Science Foundation, the U.S. Army Research Office, and the Office of Naval Research.

Mechanochemical Feedback: The Key to Complexity

According to Xiaoming Mao, a U-M professor of physics and senior author of the study, “Think of a passive soft material, like a piece of rubber. If you stretch it, it’ll slowly return to its original shape. The energy dissipates through the damping of the material. To achieve a beating heart-like behavior, we need something to counteract that dissipation, and here, we use chemical reactions.”

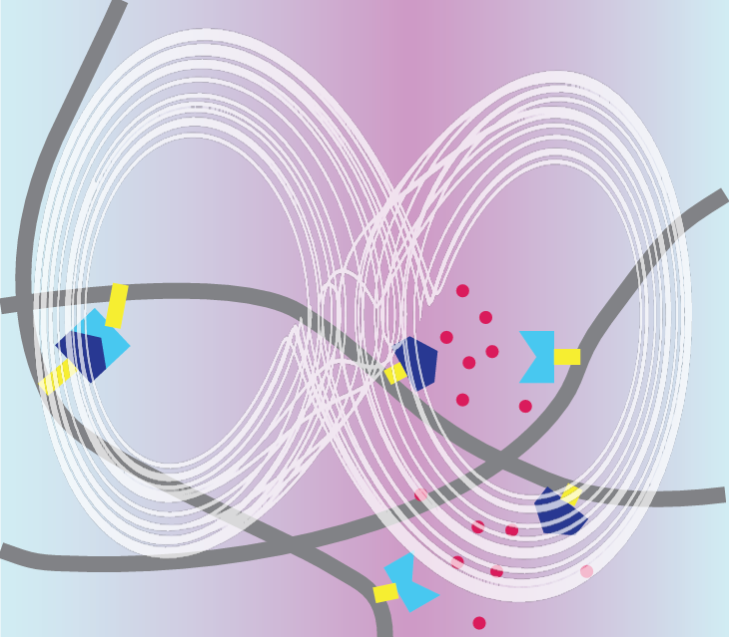

The framework’s cornerstone is the presence of reactive chemical ingredients within the material. These ingredients supply energy to the system through their reactions, which must also be sensitive to the forces exerted when the material is stressed or deformed. This coupling between reactions and mechanical force creates a positive feedback loop that counteracts the natural damping behavior, resulting in more complex motion.

“This property that is usually neglected—the inertia of the system—is actually important,” noted Biswarup Ash, a research fellow and co-author of the study. “It actually generates this interesting behavior.”

Potential Applications and Future Prospects

If the feedback loop is sufficiently strong, the material’s motion becomes chaotic, in a mathematical sense. “Imagine you have a gel that’s shivering or twitching,” Shankar described. “That’s physically what this sort of chaotic behavior would look like for an actual material.”

Although such active materials have yet to be fully realized, researchers have demonstrated individual components of the feedback cycle in other experiments. For instance, some materials change color when compressed due to a chemical reaction, while others have engineered reactions that alter the material’s shape or movement.

“As far as we know, though, these components have not been combined together,” Mao said. “But it’s plausible that in the near future, they could be, with some smart chemistry.”

Collaborative Efforts and Contributions

The study’s co-authors include Siddhartha Sarkar, a U-M postdoctoral scholar; Nicholas Boechler, a professor of engineering at the University of California, San Diego; and Yueyang Wu, a U-M undergraduate researcher. Their collaborative efforts underscore the interdisciplinary nature of this research, blending physics, chemistry, and engineering to push the boundaries of material science.

The implications of this research are vast, potentially transforming how we design and utilize synthetic materials in robotics, medical devices, and beyond. As researchers continue to explore and refine this theoretical framework, the prospect of lifelike motion in synthetic materials moves closer to reality, promising a future where machines and devices operate with the agility and responsiveness of living organisms.