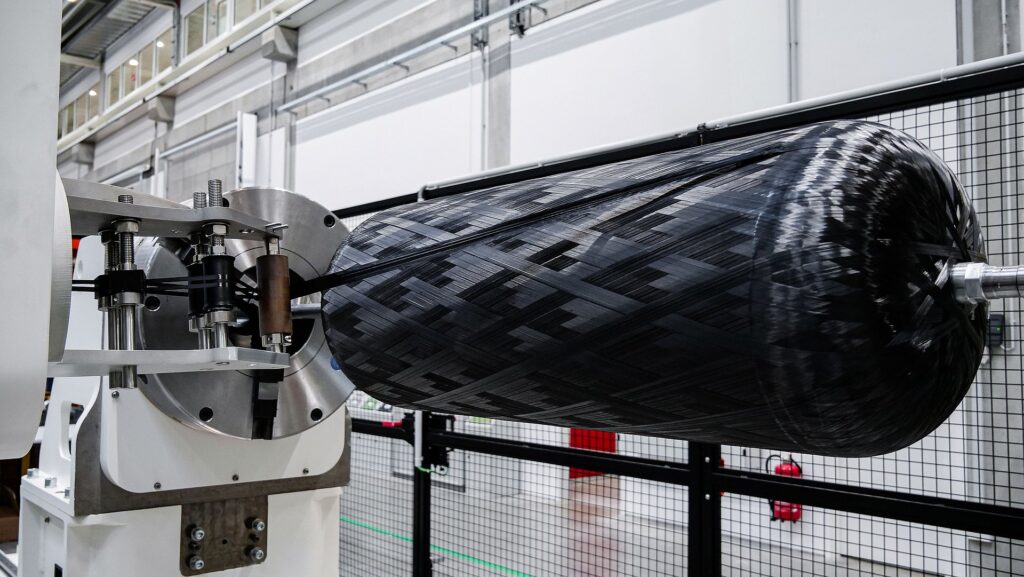

Carbon fiber, a material known for its lightweight and durable properties, is revolutionizing high-performance industries such as automotive engineering and aerospace. A start-up named Blackwave, founded at the Technical University of Munich (TUM), is at the forefront of this transformation. Initially focused on crafting custom components for sports cars and aircraft, Blackwave has now ventured into developing high-pressure tanks for space applications.

The announcement comes as the aerospace industry seeks innovative solutions to enhance rocket performance. High-pressure tanks, essential for rocket fuel systems, are traditionally made from heavy steel. However, Blackwave’s carbon fiber tanks offer a lightweight and flexible alternative, which is crucial for maintaining the structural integrity of rockets as they burn fuel and lose weight.

Engineering Innovations in Aerospace

In the realm of rocket engineering, high-pressure tanks play a pivotal role. As rockets ascend, they burn fuel stored in primary tanks, which can lead to a loss of structural stability. To counteract this, secondary tanks release noble gases to fill the empty space, maintaining the rocket’s integrity. Bastian Behrens, founder of Blackwave and a TUM alumnus, likens this process to a soda can: “It’s like a can of soda – the ratio of wall thickness to diameter is actually quite similar in aerospace. As long as the can is filled with liquid and CO₂, I can stand on it without worry. But once it’s empty, it immediately loses its structural integrity.”

Blackwave’s carbon fiber tanks are designed to withstand extreme conditions, including operating pressures of up to 420 bar and temperature fluctuations from minus 50 to plus 120 degrees Celsius. Unlike traditional spherical steel tanks, these bottle-shaped carbon tanks are easier to integrate into fuel systems, offering significant advantages in terms of weight and flexibility.

The Rise of Blackwave

Blackwave’s journey from a university project to a key player in the aerospace industry is a testament to the power of innovation and networking. Bastian Behrens, who has been fascinated by carbon fiber since his school days, found his calling at TUM’s Chair of Carbon Composites. His passion for high-performance components led him to join the TUM Student Club TUfast, where he developed carbon parts for the racing team. This experience laid the foundation for Blackwave.

“I’ve always been passionate about race cars – especially the high-performance components. That’s how I ended up at TUfast. However, I think airplanes are a bit cooler. And as a huge Star Wars and Star Trek fan – I know, an unusual combination – rockets and space were my ultimate goal,” Behrens shares with enthusiasm.

The move represents a significant shift in the application of carbon fibers, with Blackwave’s products attracting interest from renowned customers across Europe and the U.S. “The tank is the most elegant application we know today for carbon fibers. The stresses in tanks are purely tensile – and if carbon fibers excel at one thing, it’s handling tensile stress,” Behrens explains.

Support and Growth in the Innovation Ecosystem

Blackwave’s success is also attributed to the robust support system at TUM, which is recognized as one of Europe’s most successful deeptech hubs. The university’s network offers start-ups access to cutting-edge research, technical infrastructure, and market expertise. Initiatives like UnternehmerTUM, the Center for Innovation and Entrepreneurship, provide tailored support for start-up teams, helping them navigate the challenges of building a business.

Today, Blackwave employs nearly 100 people and sells its innovative products worldwide, some of which have already been successfully deployed in space. This growth is a reflection of the dynamic innovation ecosystem centered around TUM, where over 100 companies were founded in a single year, supported by UnternehmerTUM and the TUM Venture Labs.

By the Numbers: More than 1,100 start-up teams supported by UnternehmerTUM and the Venture Labs in one year.

As Blackwave continues to expand its influence in the aerospace industry, the implications of its innovations are far-reaching. The development of lightweight, durable carbon fiber tanks not only enhances rocket performance but also opens new possibilities for future space exploration. With ongoing support from TUM and its partners, Blackwave is poised to make significant contributions to the next generation of aerospace technology.

Looking ahead, the integration of carbon fiber technology in various high-performance sectors promises to drive further advancements, setting new standards for efficiency and sustainability.