HOUSTON – (Nov. 21, 2025) – In a groundbreaking development, engineers from Rice University have discovered that lab-grown diamond coatings can significantly reduce mineral buildup in industrial pipes. This advancement offers a promising alternative to traditional methods such as chemical additives and mechanical cleaning, which often provide only temporary solutions and pose environmental or operational challenges.

Mineral scaling, akin to limescale in a kettle but on a much larger and more costly scale, is a persistent issue in water and energy systems. It slows down flow, strains equipment, and increases operational costs. The study, led by Xiang Zhang, assistant research professor of materials science and nanoengineering, and Yifan Zhu, a postdoctoral researcher, highlights the potential of diamond coatings to naturally resist scale formation without the need for constant intervention.

Diamond’s Unique Properties

Diamond is renowned for its hardness, chemical stability, and ability to withstand high temperatures, making it ideal for demanding industrial environments. While previous research demonstrated diamond’s effectiveness in preventing biological fouling and bacterial growth, its impact on mineral scaling had not been thoroughly investigated until now.

The Rice University team employed microwave plasma chemical vapor deposition (MPCVD) to grow diamond films. This technique involves using methane and hydrogen gases, which are energized into a hot plasma state by microwave radiation. The process breaks apart the gas molecules, allowing carbon atoms to settle onto a silicon wafer and form a diamond structure. Postgrowth treatments were applied to manipulate the diamond’s surface chemistry.

Breakthrough Findings

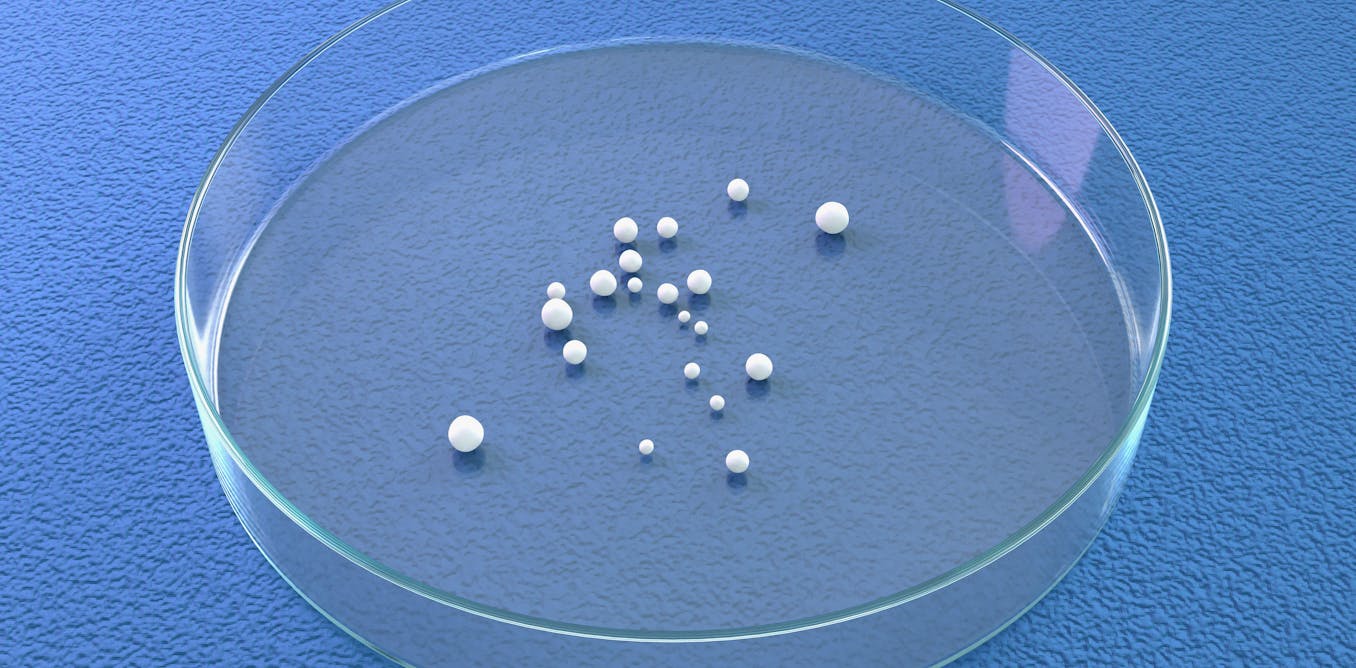

The researchers discovered that nitrogen-terminated diamond surfaces significantly outperformed those treated with oxygen, hydrogen, or fluorine. This version accumulated more than an order of magnitude less scale, with microscopy revealing only scattered crystal clusters where other surfaces formed dense layers.

“Our work addresses this urgent need by identifying a coating material that can ‘stay clean’ on its own,” said Xiang Zhang.

Molecular simulations provided insight into the phenomenon, showing that nitrogen encourages a tightly bound layer of water molecules to form on the diamond surface. This layer acts as a barrier, preventing mineral ions from attaching and initiating scale buildup.

Broader Applications and Future Implications

The team extended their research to boron-doped diamond electrodes used in electrochemical systems, which also showed reduced scale accumulation without a loss in performance. This comprehensive study, which included combined microscopy, chemical analysis, and adhesion measurements, was previously limited by the cost and availability of high-quality diamond films and reliable surface treatment methods.

“These findings identify vapor-grown, cost-effective, polycrystalline diamond films as a powerful, long-lasting anti-scaling material with broad potential across water desalination, energy systems, and other industries where mineral buildup is a problem,” said Pulickel Ajayan, professor of materials science and nanoengineering.

Jun Lou, another professor involved in the study, emphasized the scalability and versatility of the diamond coating deposition process, making it attractive for various industry sectors.

Support and Acknowledgments

The research received support from several organizations, including the National Science Foundation, the Welch Foundation, and Brazilian agencies such as the São Paulo Research Foundation and the National Council for Scientific and Technological Development. The authors acknowledge that the content of the study reflects their views and not necessarily those of the funding bodies.

This innovative use of lab-grown diamonds marks a significant advancement in industrial maintenance technology, offering a sustainable and efficient solution to a long-standing problem. As industries continue to seek ways to improve efficiency and reduce costs, the potential applications of diamond coatings are vast and promising.