For centuries, humans have crafted beautiful and functional objects from the natural world. While ancient artisans lacked today’s precision tools and scientific insights, their creations have endured, inspiring modern researchers seeking sustainable solutions. This trend is evident in the renewed interest in traditional crafts, particularly in architecture, materials, and textiles.

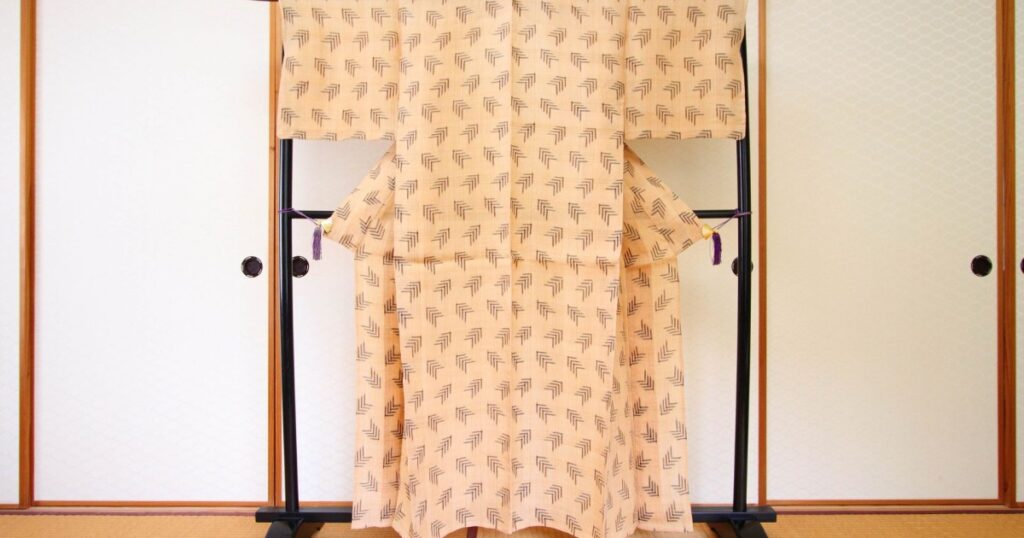

Summers in Okinawa Prefecture are known for their oppressive heat and humidity. While air conditioning is a modern solution, historical Okinawans found comfort through ingenious design and textiles. Traditional Okinawan homes, with their low, open plans and thick coral or limestone walls, harnessed breezes while withstanding typhoon winds. Meanwhile, Bashofu textiles, crafted from banana fibers, provided cool, dry, and remarkably soft clothing.

Reviving Ancient Techniques for Modern Sustainability

Recently, scientists have turned their attention to Bashofu to understand its adaptation to subtropical climates. A study published in Scientific Reports by researchers at the Okinawa Institute of Science and Technology (OIST) delves into how Bashofu techniques modify banana plant fibers to create soft, durable, and breathable fabrics. “Artisans have built up their intuition of how to create these textiles since at least the 16th century,” explains Dr. Yoko Nomura of OIST. “And now, we have grounded these intuitions in modern plant science.”

The Intricacies of Bashofu Craftsmanship

The Okinawan banana, Musa balbisiana var. liukiuensis, known as Itobashou, is central to Bashofu textiles. Specifically, the pseudostem’s innermost fibers, called Nahagu, are used for weaving due to their softness and strength. As fibers age outwardly, they become stronger but less pliable. The outermost fibers, Waha, are typically reserved for interior textiles. “Artisans use the feel and color of the material to differentiate fibers,” notes Dr. Koji Koizumi of OIST. “Our imaging analysis shows that Nahagu fibers have thinner cell walls than Waha fibers, yet artisans distinguish them by touch and color.”

Creating one high-quality kimono requires fibers from at least 200 pseudostems, demanding efficiency and skill from the artisan.

Scientific Insights and Preservation Efforts

Bashofu involves 23 processing steps from stem to textile. While lab-based techniques have been explored, none match the quality achieved by traditional methods. The research team aims to document each processing step’s impact on fiber properties, test tensile strengths, and study fiber cell morphology through advanced imaging. This work seeks to preserve Bashofu for future generations and lay a foundation for further research into this climate-adapted craft.

“We have a close relationship with the artisans who maintain this craft, and we’re grateful for the materials they provide,” says Dr. Nomura. “Bashofu’s honeycomb fiber structure effectively wicks sweat away from the skin, and both the process and product are highly sustainable. It’s a cultural and scientific treasure we aim to preserve.”

The Broader Implications of Bashofu

The renewed focus on Bashofu underscores a broader movement towards sustainable practices in textiles and beyond. As climate change continues to challenge traditional industries, the lessons from Bashofu offer valuable insights into how ancient techniques can inform modern sustainability efforts. By marrying traditional craftsmanship with scientific research, there is potential to develop new materials that are both environmentally friendly and culturally significant.

Looking forward, the integration of traditional knowledge with contemporary science could pave the way for innovative solutions in sustainable design and material science. The preservation and study of crafts like Bashofu not only honor cultural heritage but also contribute to global efforts in sustainability, offering a blueprint for future innovations.