A groundbreaking study from researchers at The University of Texas at Austin and the University of Porto has introduced a novel approach to cancer treatment using tin-based nanomaterials combined with near-infrared light. This innovative method promises to deliver less toxic and more affordable cancer therapies, leveraging light rather than traditional drugs or radiation.

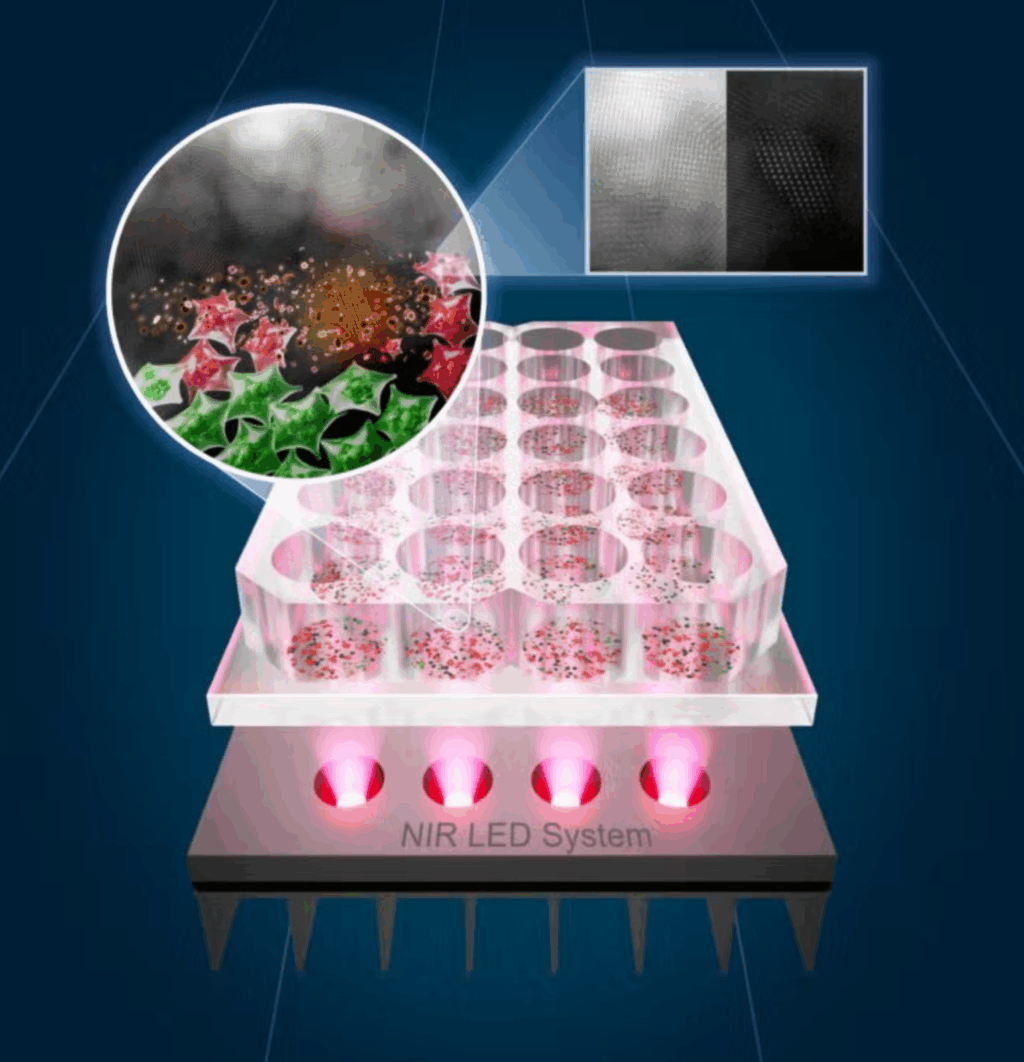

The core of this breakthrough lies in the use of tin oxide nanoflakes, or SnOx, which are created through a straightforward electrochemical process that transforms tin disulfide (SnS₂) into a new, more effective structure. These nanoflakes have the unique ability to absorb near-infrared (NIR) light and convert it to heat, selectively destroying cancer cells while leaving healthy cells unharmed. This photothermal therapy precisely targets tumors by generating heat wherever light is concentrated.

Converting Tin into a Cancer Killer

The researchers initiated their process with layered SnS₂ nanosheets, which they then electrochemically oxidized into SnOx nanoflakes. This transformation introduced tiny imperfections known as oxygen vacancies—crucial defects that enhance the material’s capacity to absorb light and emit heat.

Electron microscopy revealed that the oxidized flakes were thinner and more porous than their original form, providing a larger surface area for light interaction. This structural change, coupled with a novel chemical composition, significantly improved their efficiency in converting light into heat.

“They rapidly heated up water solutions to above 60°C, a temperature lethal to cancer cells, when irradiated with NIR at 808 nanometers—the optimal wavelength for deep tissue penetration. The photothermal conversion efficiency was recorded at 45.6%, markedly higher than that of the control material.”

Safe, Targeted, Reusable

In laboratory tests, the nanoflakes demonstrated low toxicity to cancer cells in the absence of light, indicating that the particles are non-toxic in the dark. However, when exposed to NIR light, they effectively killed cancer cells. In tests on colorectal and skin cancer cells, a 30-minute treatment eradicated up to 92% of skin cancer cells and half of the colorectal cancer cells, while sparing healthy human skin cells.

Fluorescence microscopy showed the nanoflakes infiltrating cancer cells and dispersing through their cytoplasm. Upon activation, the flakes emitted heat bursts that penetrated membranes, inducing apoptosis—cell death—without harming surrounding tissue.

The nanoflakes also proved durable, maintaining their structure and function through multiple heat and cool cycles. They remained stable in water storage, retaining their optical properties over extended periods, making them viable for medical use.

LEDs Instead of Lasers

One of the major advancements in this study is the replacement of costly, high-power lasers with light-emitting diodes (LEDs). LEDs offer a more economical and safer energy source, facilitating treatment scalability and enhancing safety for clinical applications.

“It’s our aspiration to bring this technology to patients worldwide,” stated Artur Pinto, a scientist at the University of Porto and co-senior author of the study. He envisions a handheld LED device for skin cancer that patients could use at home post-surgery, providing site-specific light treatment to eliminate residual cancer cells and minimize recurrence risk.

This shift towards LED-based therapy could revolutionize light-based treatments in hospitals and homes, particularly in regions lacking access to large equipment.

The Science Behind the Glow

The secret to the nanoflakes’ success lies in oxygen vacancies—minute spaces in the atomic lattice that alter the material’s light response. These vacancies create new electronic states that broaden the range of NIR wavelengths absorbed, enhancing photon capture and heat generation.

Computer modeling confirmed that oxidized tin oxide has a reduced bandgap, allowing it to absorb more light energy and convert it to heat rather than reflected light. This synergy of nanostructure design and defect engineering results in a material that is both efficient and adaptable. Researchers can even tailor its response by modifying oxidation conditions.

Compared to other photothermal materials, such as gold nanorods or carbon materials, SnOx nanoflakes are cost-effective, chemically stable, and environmentally friendly. The entire fabrication process occurs at room temperature without toxic chemicals, providing a sustainable and scalable method for medical nanomaterial production.

Looking Ahead

The research team plans to further investigate the nanoflakes by testing them in live animal models to assess their circulation and long-term safety within the body. They are also exploring ways to combine the particles with other catalytic materials for broader medical applications.

The technology’s potential extends beyond cancer treatment. The same light-activated heat could be applied in antimicrobial therapy or wound healing, where focused heat accelerates recovery.

“This is a step towards light-based medicine that’s not only powerful but practical,” summarized Jean Anne Incorvia, a professor at UT Austin’s Cockrell School of Engineering.

Practical Implications of the Research

The development of SnOx nanoflakes represents a significant advancement in cancer treatment, offering a noninvasive, targeted, and cost-effective alternative therapy. The combination of LED light and tin nanoflakes could make photothermal therapy more accessible to hospitals and clinics worldwide.

Eventually, portable devices could bring post-surgery light therapy into patients’ homes, particularly for surface cancers like melanoma. This research contributes to making cancer treatment more tolerable for patients by reducing reliance on chemotherapy and radiation, offering a less expensive and less infrastructure-intensive solution. It provides hope for patients in both advanced and resource-limited healthcare systems.

Research findings are available online in the journal ACS Nano.