Protein nanocages, known for their hollow structures and versatility in medical applications like drug and vaccine delivery, are now being hailed as a groundbreaking solution for metal recovery. Researchers at the University of Pittsburgh have demonstrated that ferritin, a class of protein nanocage, can effectively separate and concentrate metal ions from solutions. This discovery opens a promising pathway for processing critical-metal-containing leachates from recycled e-waste and batteries.

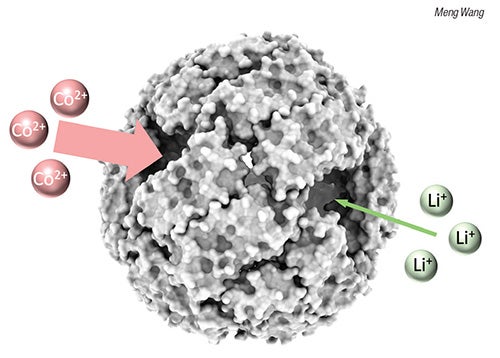

In experiments involving mixtures of cobalt and lithium, ferritin selectively adsorbs cobalt, leaving lithium in solution.

“Ferritin has a spherical structure, and it takes up metal ions from solution, concentrating them in its cavity. It is like a nano-sized concentrator that can constantly collect metal ions. We have seen that the concentration of metal ions inside the cage can be hundreds to thousands of times higher than the concentration in the solution,”

explains Meng Wang, assistant professor of civil and environmental engineering.

Innovative Metal Recovery Process

The ability to cultivate a high local concentration of metal ions simplifies the downstream precipitation process compared to traditional methods. Wang notes,

“Because the metal ions are highly concentrated within the cage, we can do the precipitation at very benign conditions. We don’t have to go to high pH, like 10, 11 or higher, to do the precipitation, which is commonly required using other methods. We can do the precipitation at a pH of 7 or 8.”

This process, when carbonate ions are added at these mild pH values, results in cobalt carbonates with over 95% purity.

Additionally, many conventional metal-recovery processes depend on organic solvents, hazardous chemicals, or high temperatures, none of which are necessary when using ferritin nanocages. This represents a significant advancement in creating more environmentally friendly and sustainable metal recovery solutions.

Potential for Scale-Up and Commercialization

Currently, Wang’s team has demonstrated the efficacy of ferritin with cobalt-lithium and nickel-lithium mixtures at the laboratory scale. However, the potential for scaling up is on the horizon.

“Expressed proteins can self-assemble into this nanocage structure, and it requires minimal post-processing, so that means scaleup could be relatively easy using commercially available reactors and fermenters,”

Wang says.

The next steps involve material and process improvements to enhance ferritin’s selectivity and enable continuous processing. There is also a focus on reusing the protein nanocages for multiple cycles, which could lower costs for larger-scale processing. These findings were published in the journal Environmental Science and Technology Letters, highlighting the potential for significant impact in the field of sustainable metal recovery.

Broader Implications and Future Directions

The announcement comes as the global demand for critical metals continues to rise, driven by the proliferation of electronic devices and the push towards renewable energy technologies. The ability to efficiently recover metals from e-waste not only addresses environmental concerns but also reduces reliance on traditional mining, which is often resource-intensive and environmentally damaging.

According to industry experts, the development of such technologies could revolutionize the recycling industry, making it more efficient and sustainable. As the world grapples with the challenges of e-waste management, innovations like ferritin nanocages offer a glimpse into a future where technology and sustainability go hand in hand.

Meanwhile, researchers are optimistic about the broader applications of protein nanocages beyond metal recovery. Their unique properties could lead to advancements in other fields, such as targeted drug delivery and biosensing, further showcasing their versatility and potential to drive innovation across various industries.

As the research progresses, the scientific community and industry stakeholders will be watching closely to see how these developments unfold and what they might mean for the future of sustainable technology and resource management.